Which Formlabs 3D Printer Should I Buy?

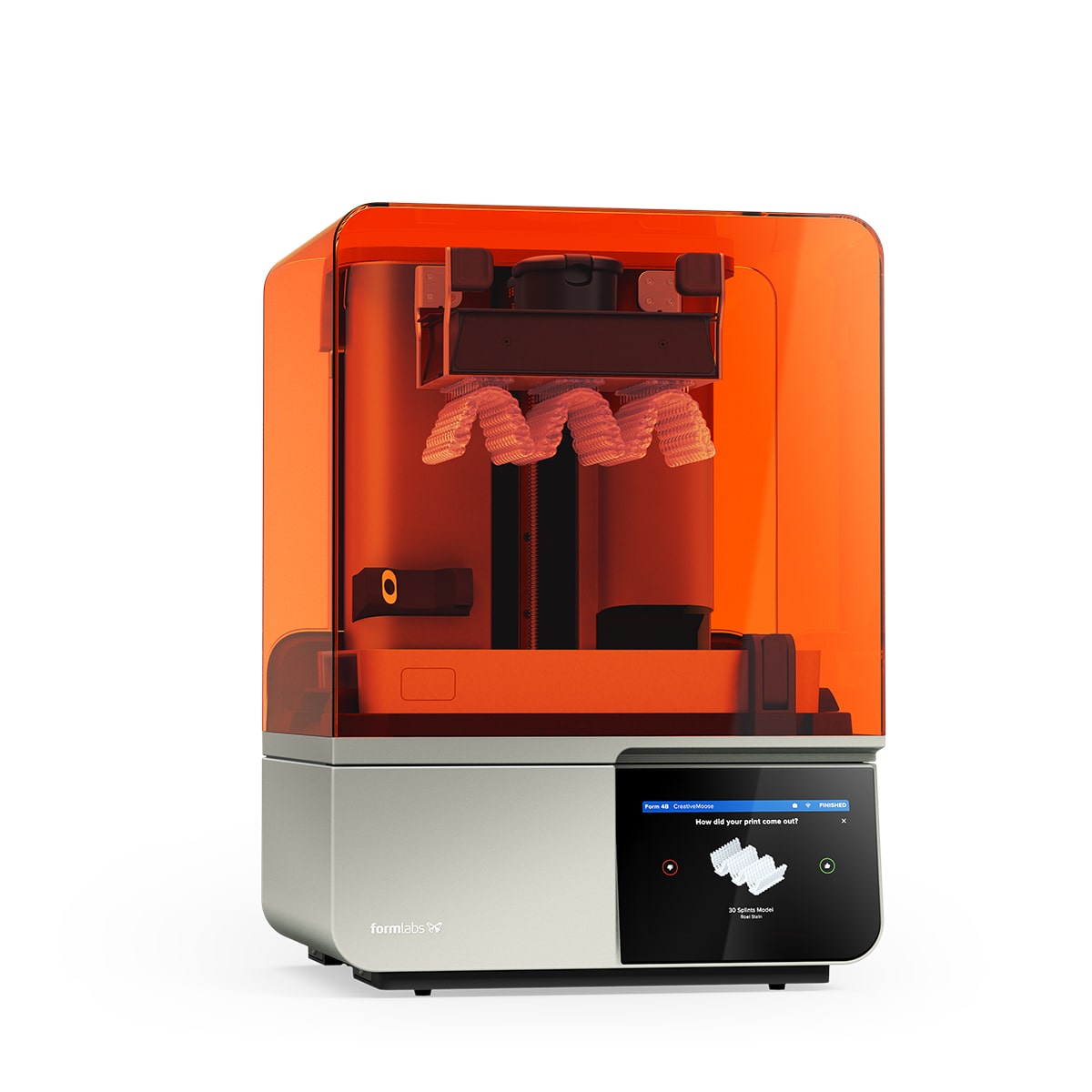

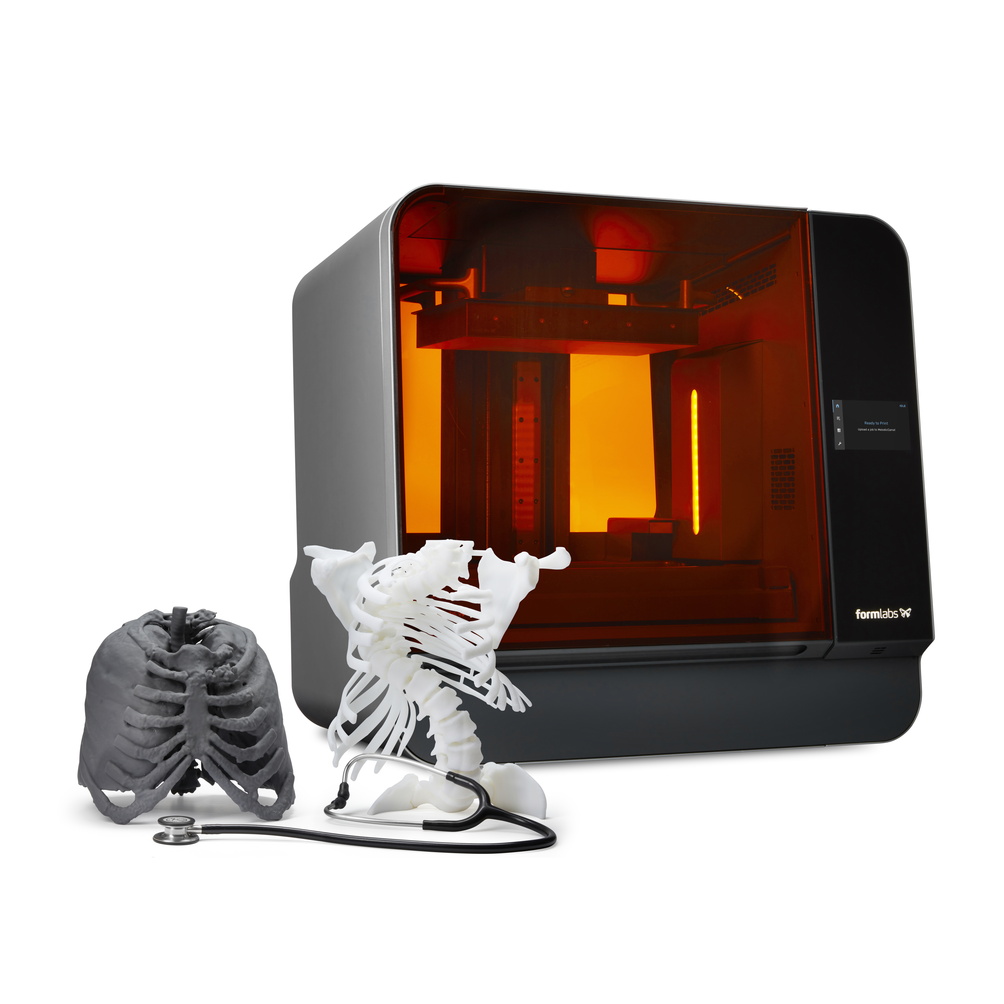

Medical and dental professionals usually choose the Form 4B or Form 4BL for SLA Printing. The B in Formlabs printers stands for Biocompatible, meaning that the printers can use medical and dental resins. Additionally, some materials for the Fuse 1+ 30W may be skin safe or sterilisable. To find out more contact our team.

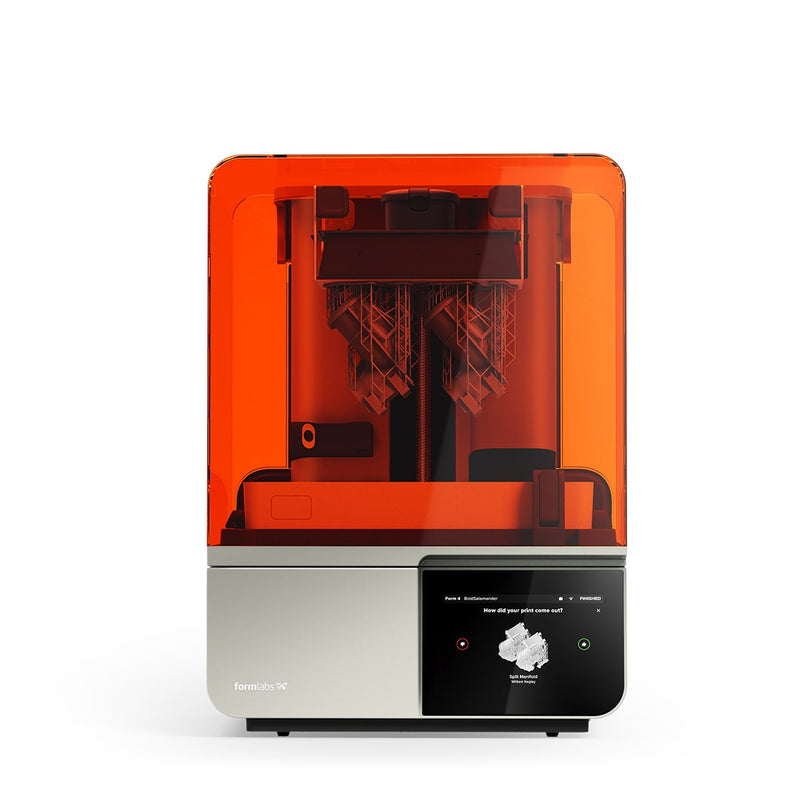

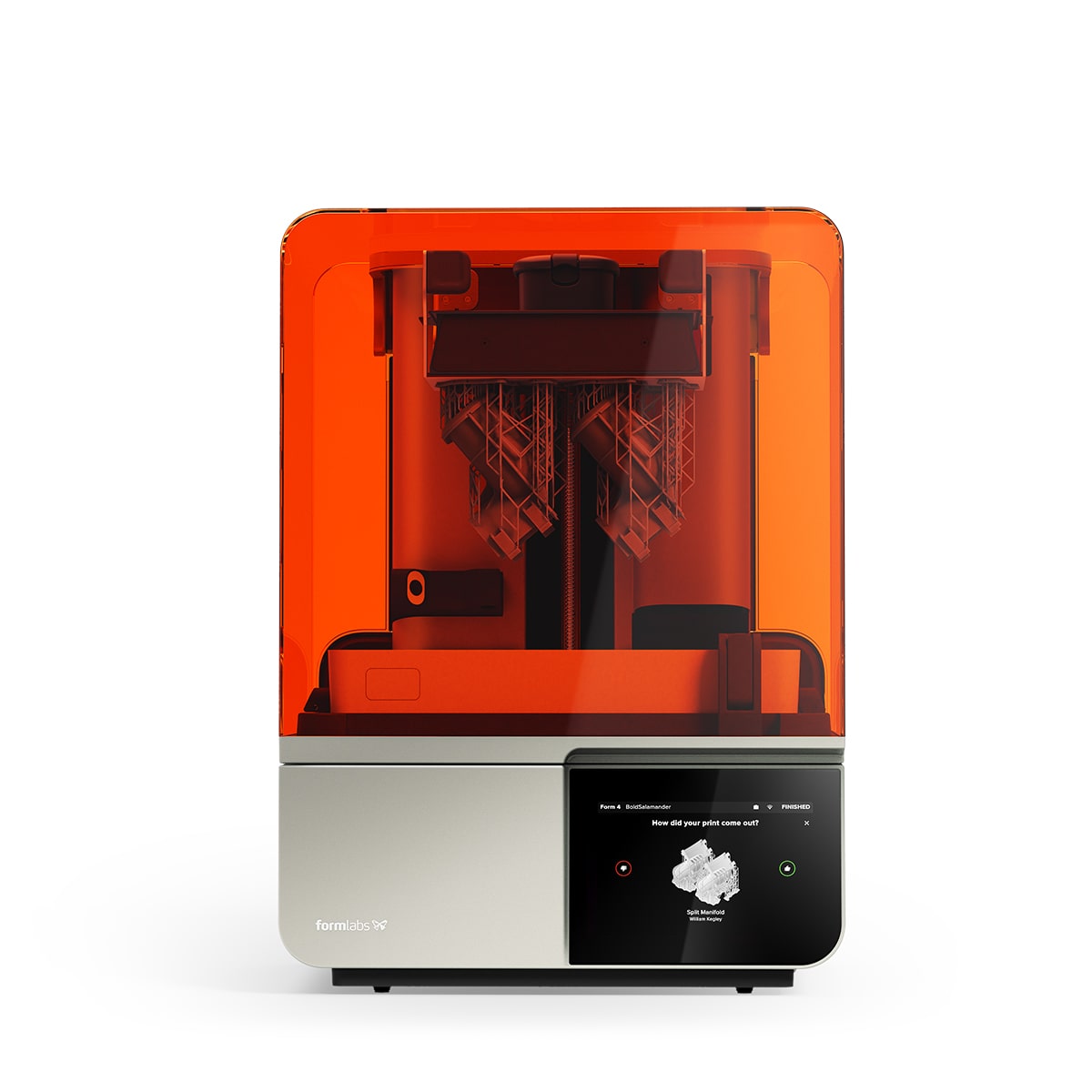

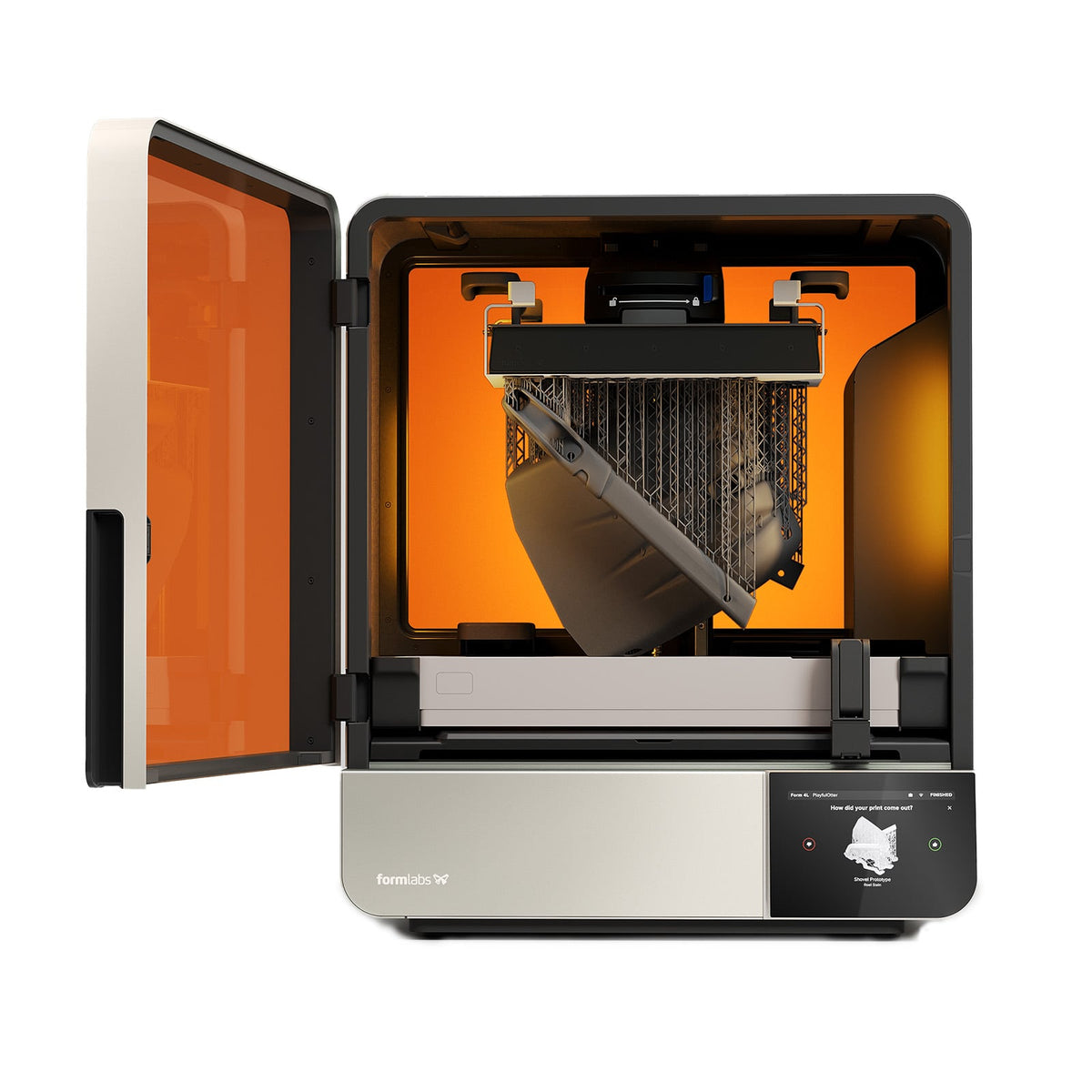

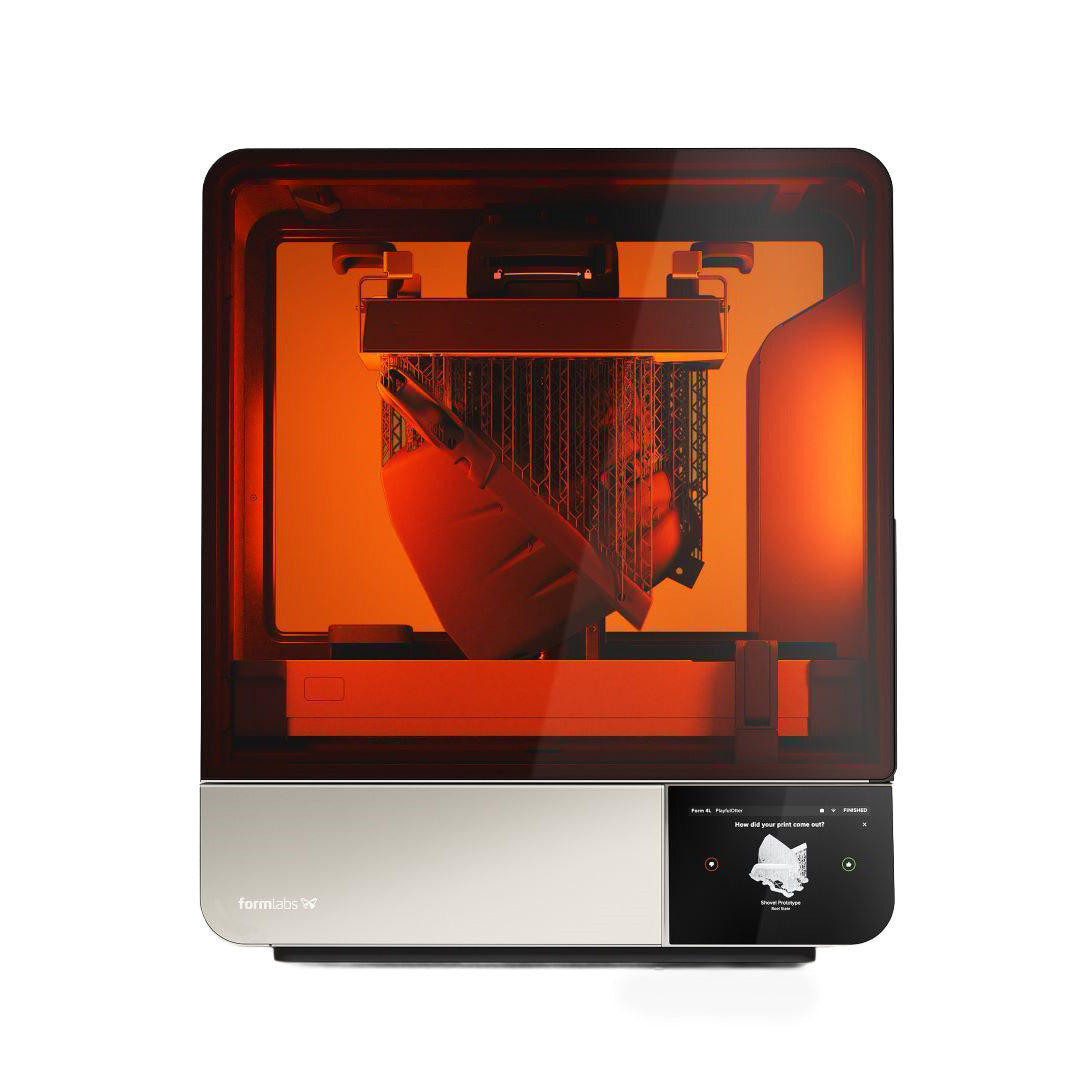

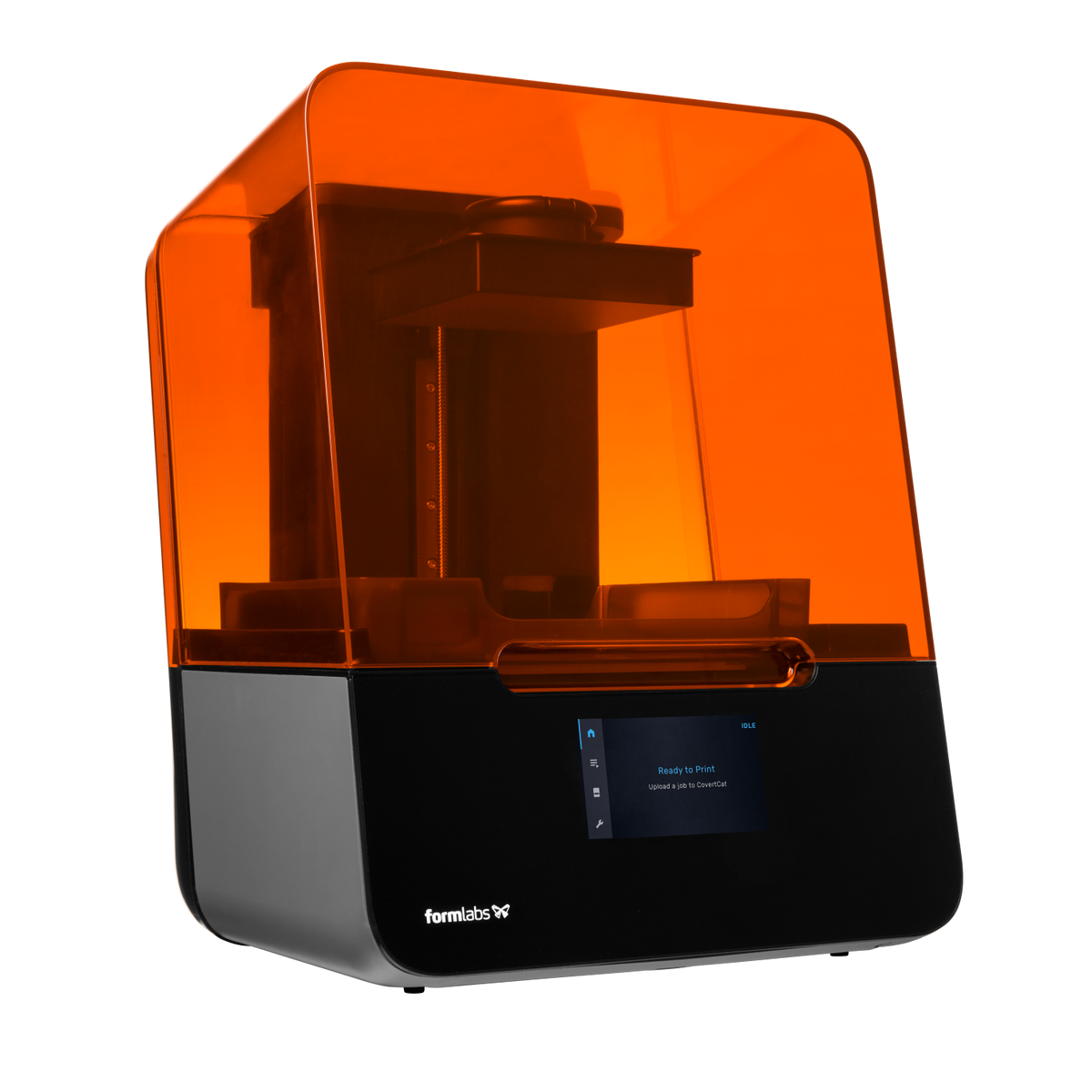

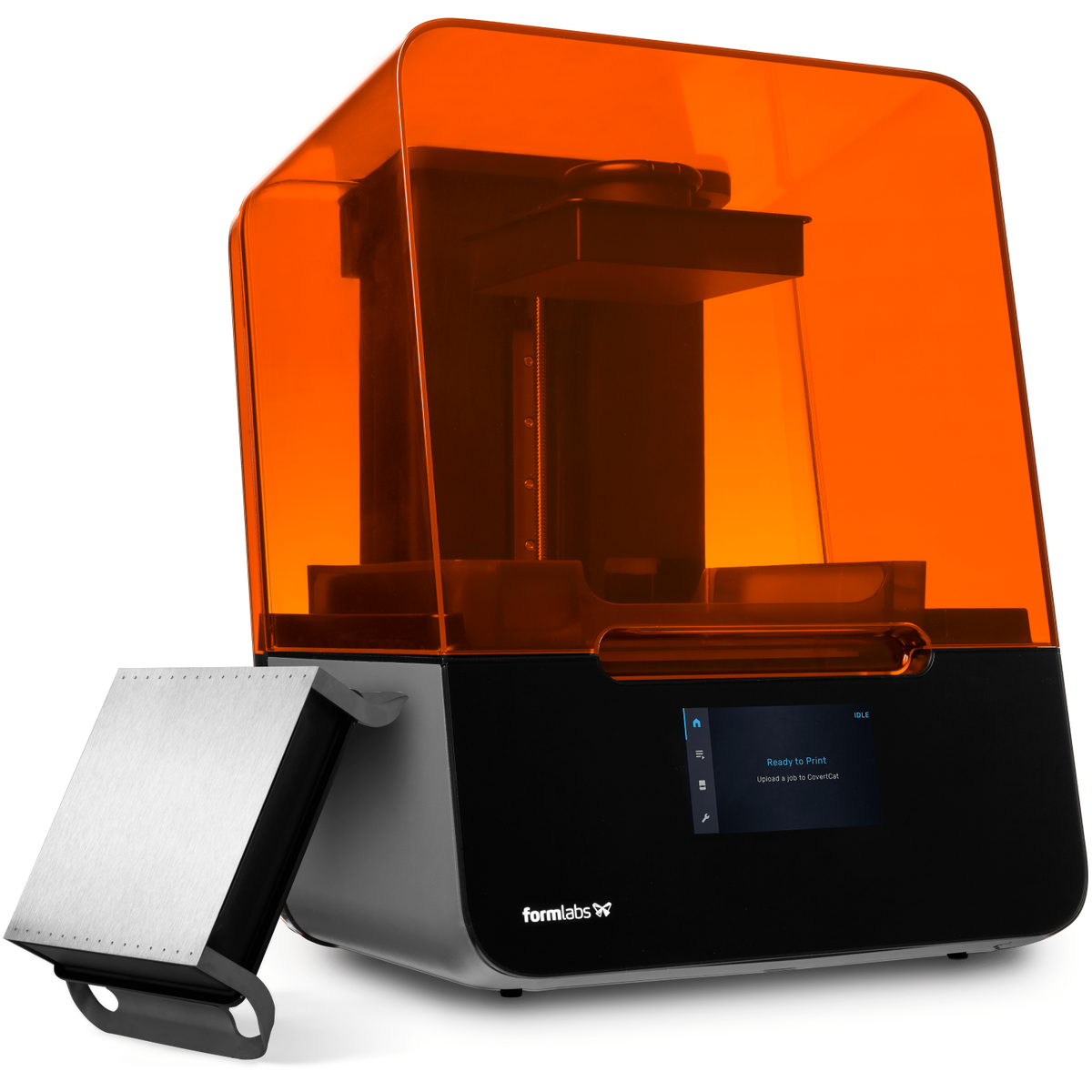

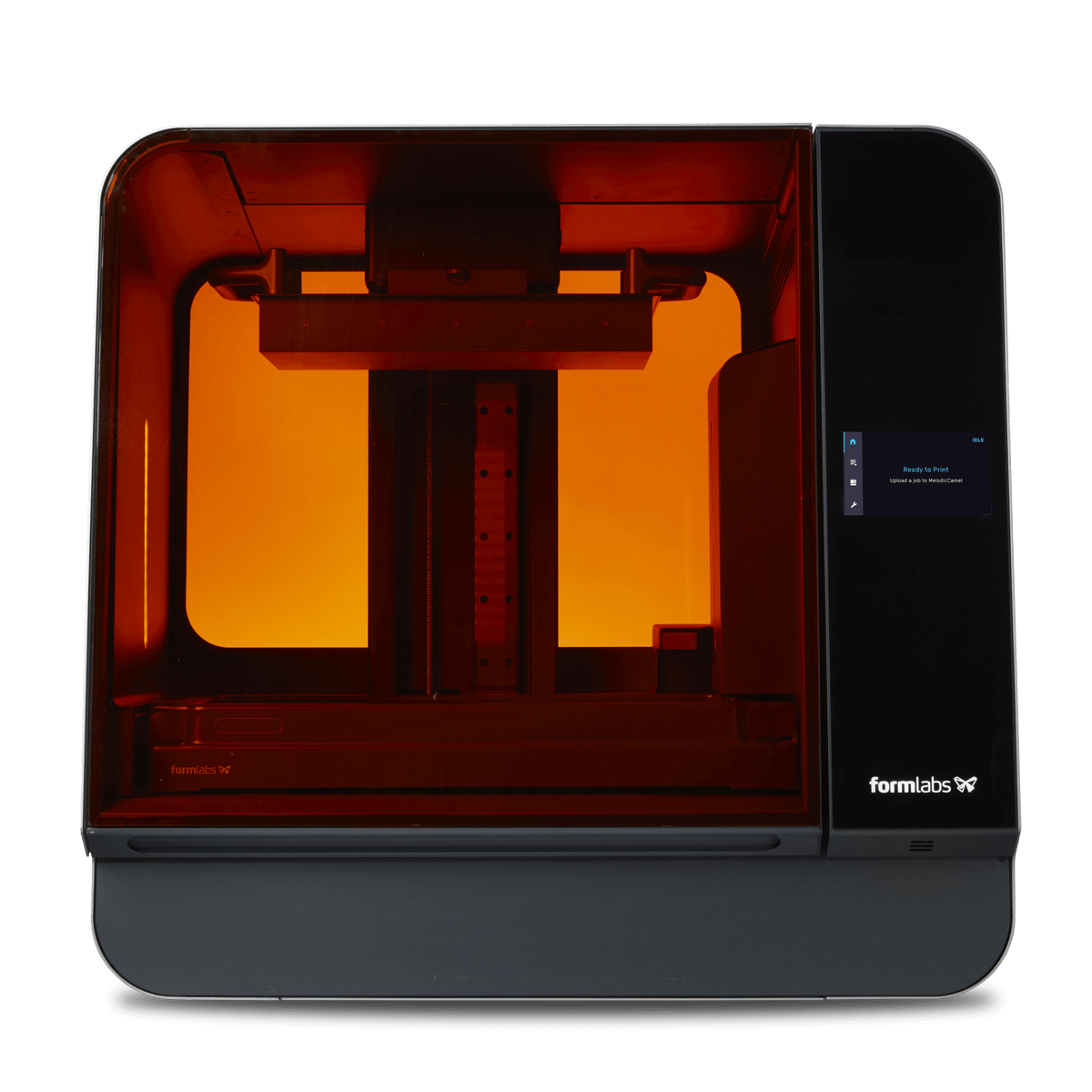

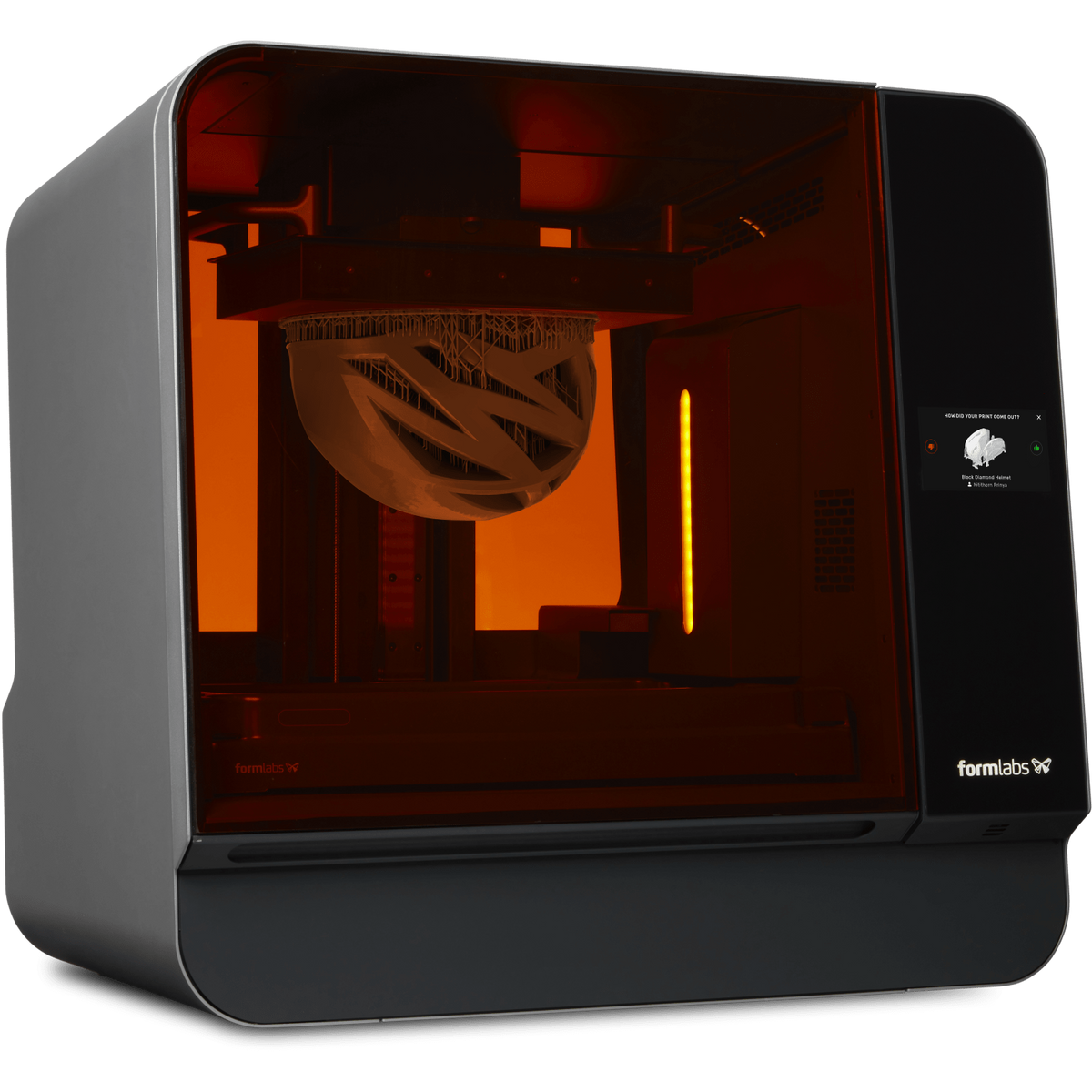

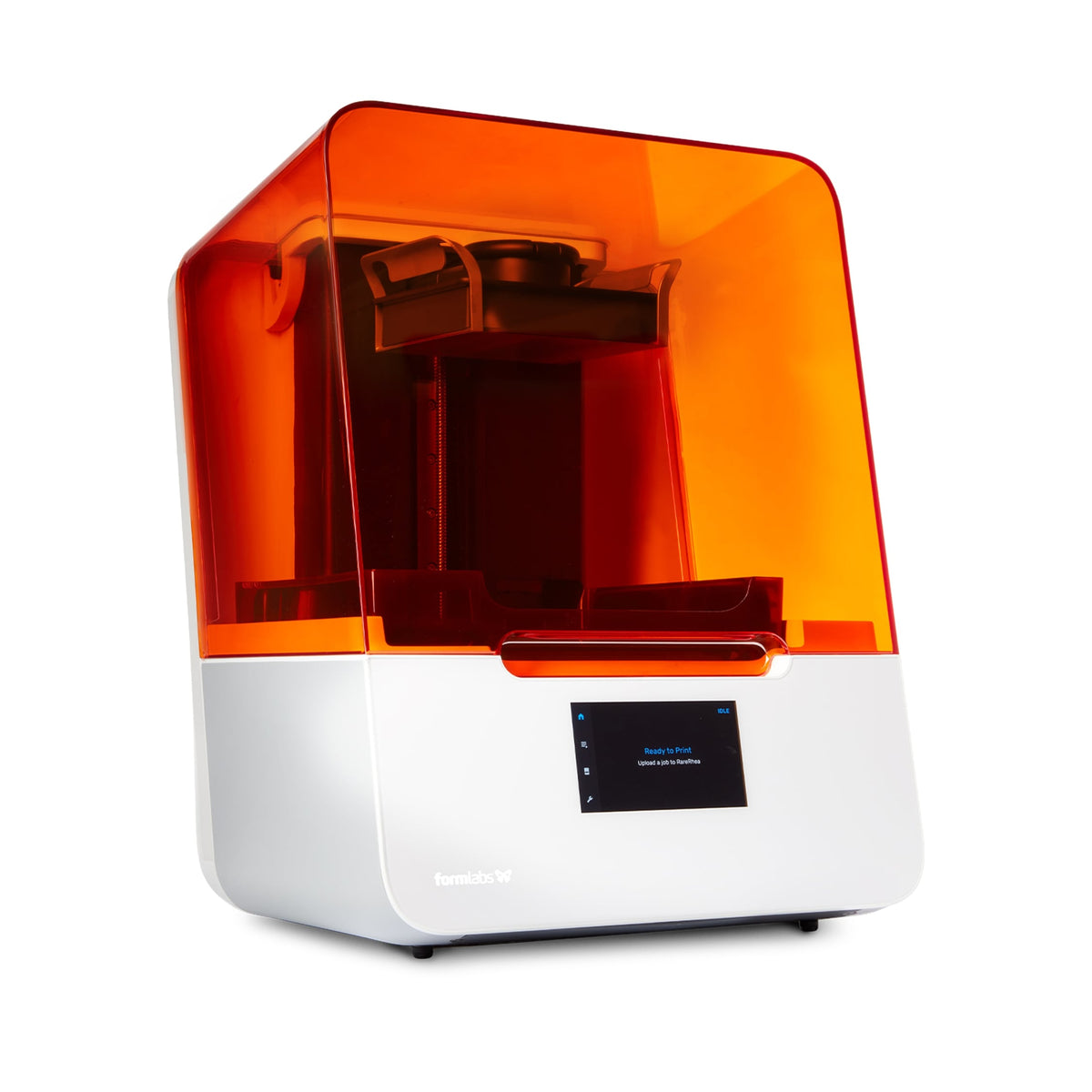

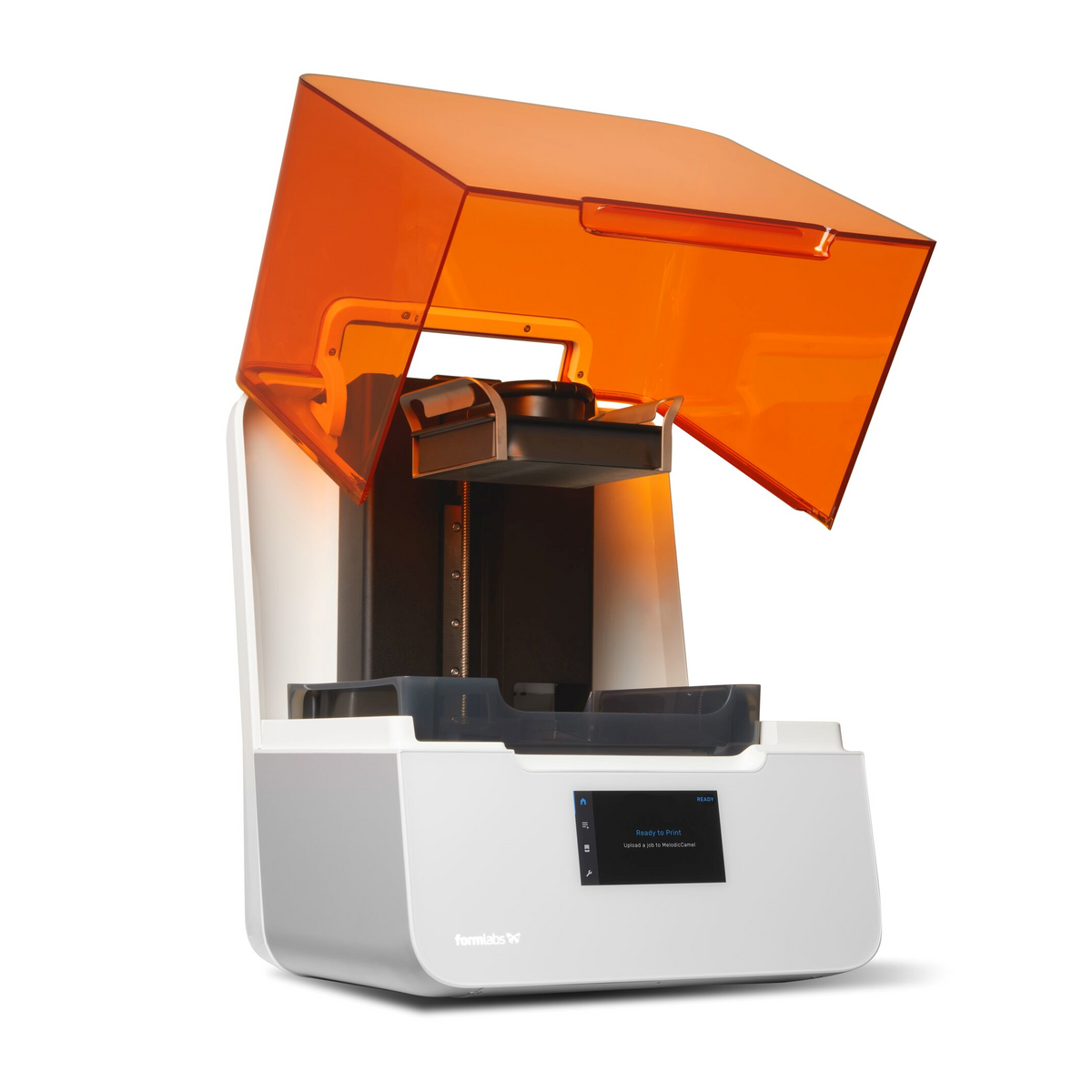

For general purpose, engineering, and jewellery use-cases, choose any printer without a B in the name. SLA 3D printers include the Form 4 and Form 4L while the the Fuse 1+ 30W is a brilliant SLS 3D printer.

Optimum talks about the benefits the Form 4L and Form 4 have had for his business.

Form 4L & Form 4 Review - Optimum Tech

Frequently Asked Questions

As accesible 3D printing is still an emerging technology for many people, it is common for potential users to have questions regarding Formlabs 3D Printers.

If you can't find the asnwer to your question below, please feel free to contact us.

What is the Difference Between Formlabs SLA and SLS 3D Printers?

Formlabs 3D printers are currently one of two 3D printing technologies. This includes SLA 3D printing and SLS 3D printing.

Formlabs Form lineup of printers use SLA or Stereolithography to cure each layer of a 3D Print.

This is different to Formlabs Fuse 1+ 30W printers which use SLS or Seletive Laser Sintering to "Fuse" each layer of the print.

SLA (Stereolithography) works by using a laser to cure UV sensitive resins into hardened plastic, layer by layer.

SLA 3D printing has become popular for its ability to produce high accuracy, isotropic, and watertight parts.

The printers can use a range of advanced materials that create fine features and a smooth surface finish.

To learn more about how SLA technologies work, read the whitepaper "Intro to Stereolithography 3D Printing".

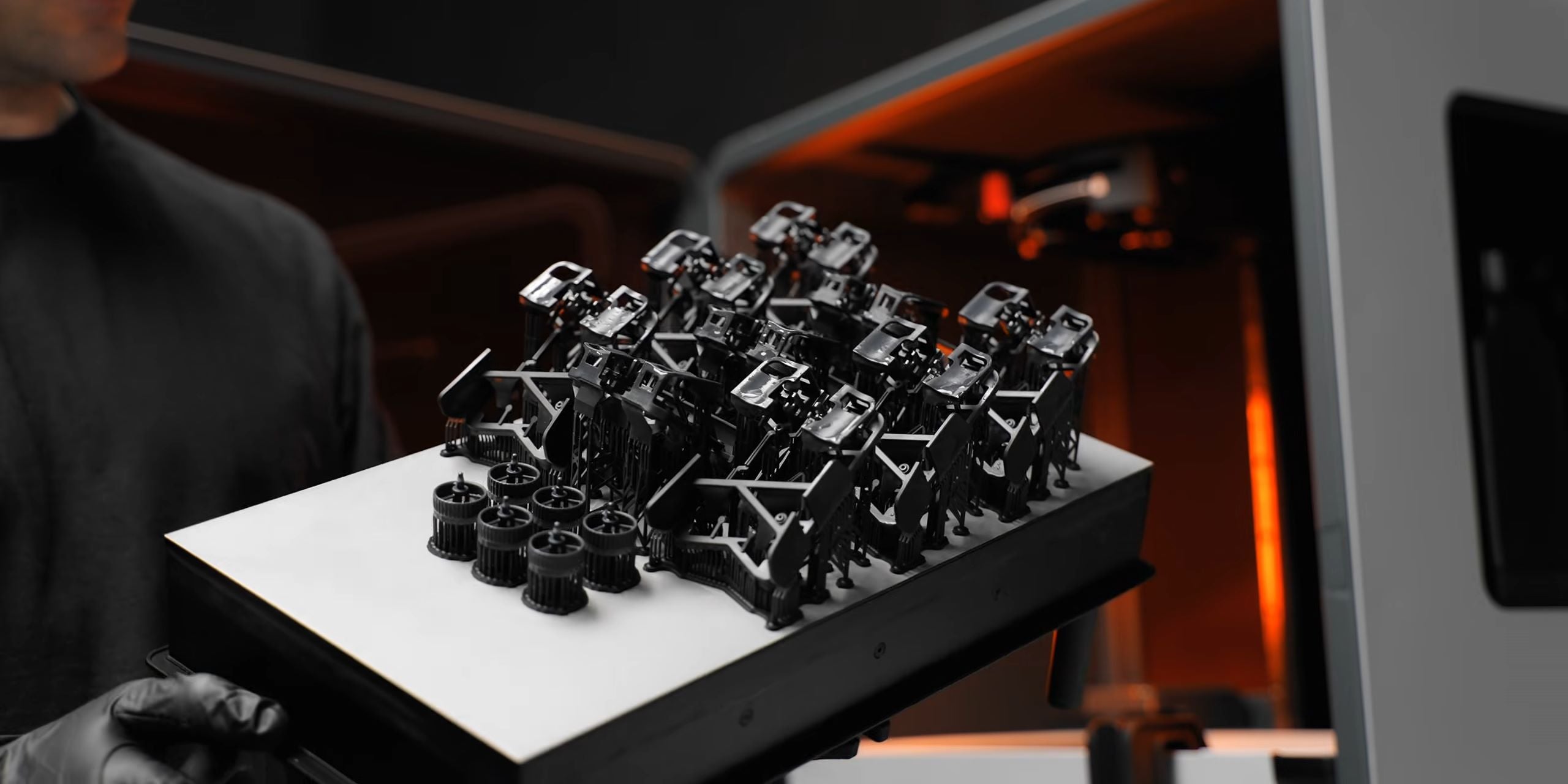

SLS (Selective Laser Sintering) works by using a high-power laser to sinter powder into a solid 3D structure.

SLS 3D printing has been a popular choice for engineers and manufacturers for decades. Low cost per part, high productivity, and established materials make the technology ideal for a range of applications.

Recent advances in machinery, materials, and software have made SLS printing accessible for a wider range of businesses.

To learn more about SLS 3D printing, read the whitepaper “Guide to Selective Laser Sintering (SLS) 3D Printing”.

What Are Biocompatible 3D Printers?

The "B" for Formlabs 3D Printers stands for Biocompatible.

This means that printers such as the Form 4B and Form 4BL can use biocompatible resins including the BioMed family and more.

If you are a medical professional consider the Form 4B and Form 4BL as your primary SLA printer options.

The Fuse 1+ 30W may also use skin safe or sterilisable powders. Please contact us for more information.

FDM vs SLA vs SLS

All 3D Printing technlogies create layers that form the final part or poduct.

FDM (Fuse Deposition Modeling) prints the layers by extruding heated plastic through a small nozzle.

SLA (Stereolithography) prints the layers by using a laser to cure UV sensitive resins.

Finally, SLS (Selective Laser Sintering) uses a laser to sinter, or fuse, layers of powder into the desired shape.

FDM 3D printers are cost effective and can be good for proof of concept models. However, the technology has the lowest resolution and accuracy, meaning the final parts will have more visible layer lines and less detail. FDM printers are not recommended for some complex designs or end-use parts.

SLA 3D printers are affordable, have high accuracy, and create smooth surface finishes. The technology is recommended for creating nice looking products with good mechanical properties and high resolution.

SLS 3D printers are most common for industrial or commercial applications. Parts or products created by SLS printers are strong, cost-effective, and suitable for demanding end-use environments.

To find out more, visit this article which compares FDM vs SLA vs SLS.