Fuse 1

Package Options

For 3D printer systems, we recommend contacting our team so we can confirm any lead times and provide a custom quotation to suit your application.

Fast shipping on in-stock items now available for Perth and Eastern States.

The Fuse 1+ 30W Supersedes the Fuse 1

Please note that the Fuse 1 is no longer being sold and has being superseded by the Fuse 1+ 30W. Pricing on this page reflects the Fuse 1+ 30W pricing. Online orders will be the Fuse 1+ equivalents.

Contact our team to learn more about the improvements of the Fuse 1+ 30W.

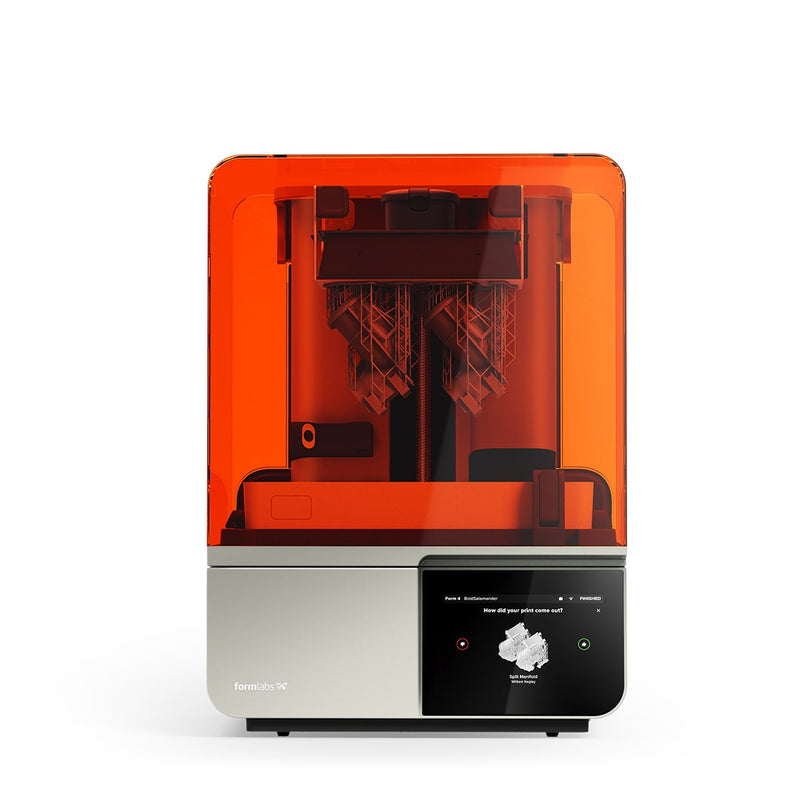

Fuse 1

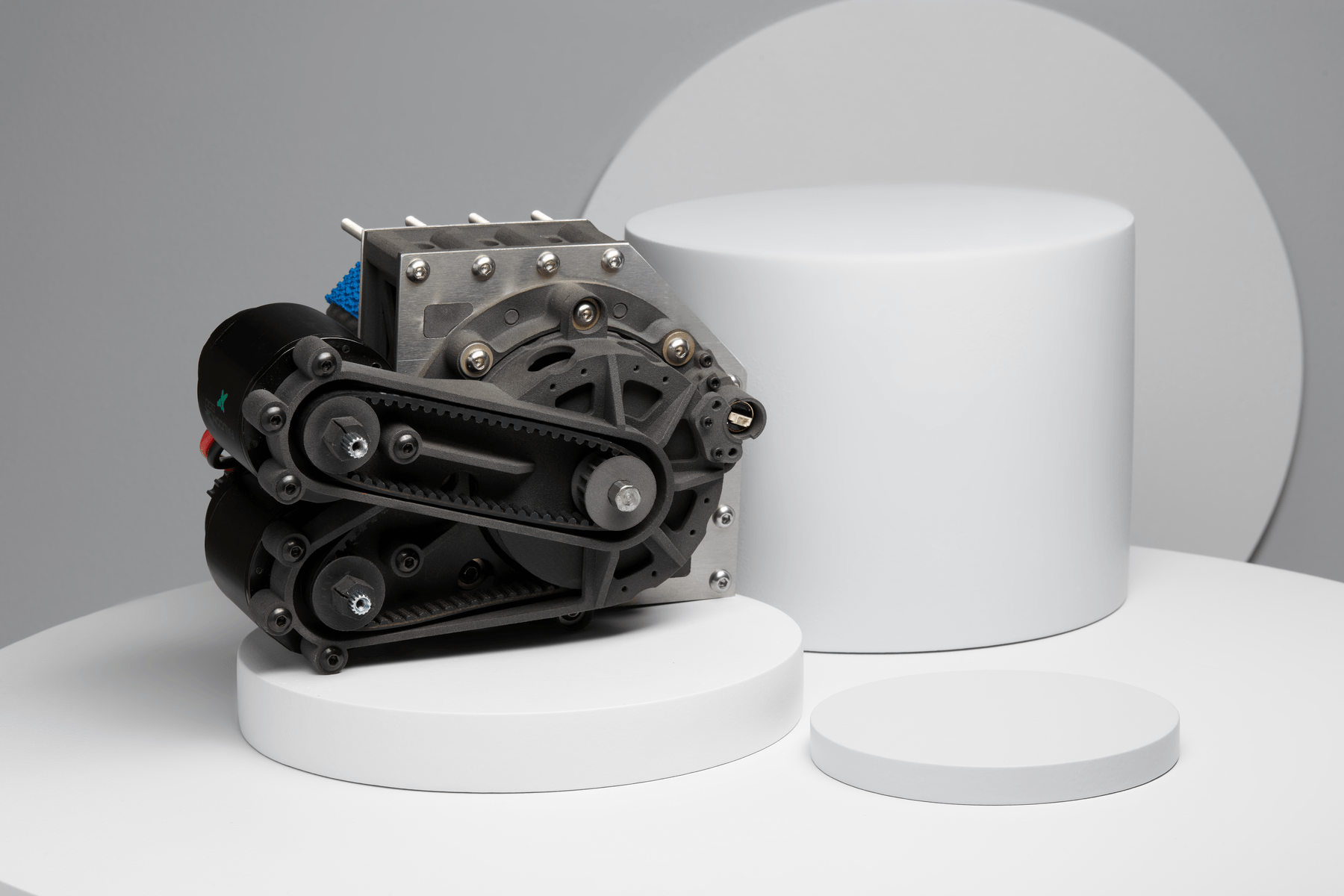

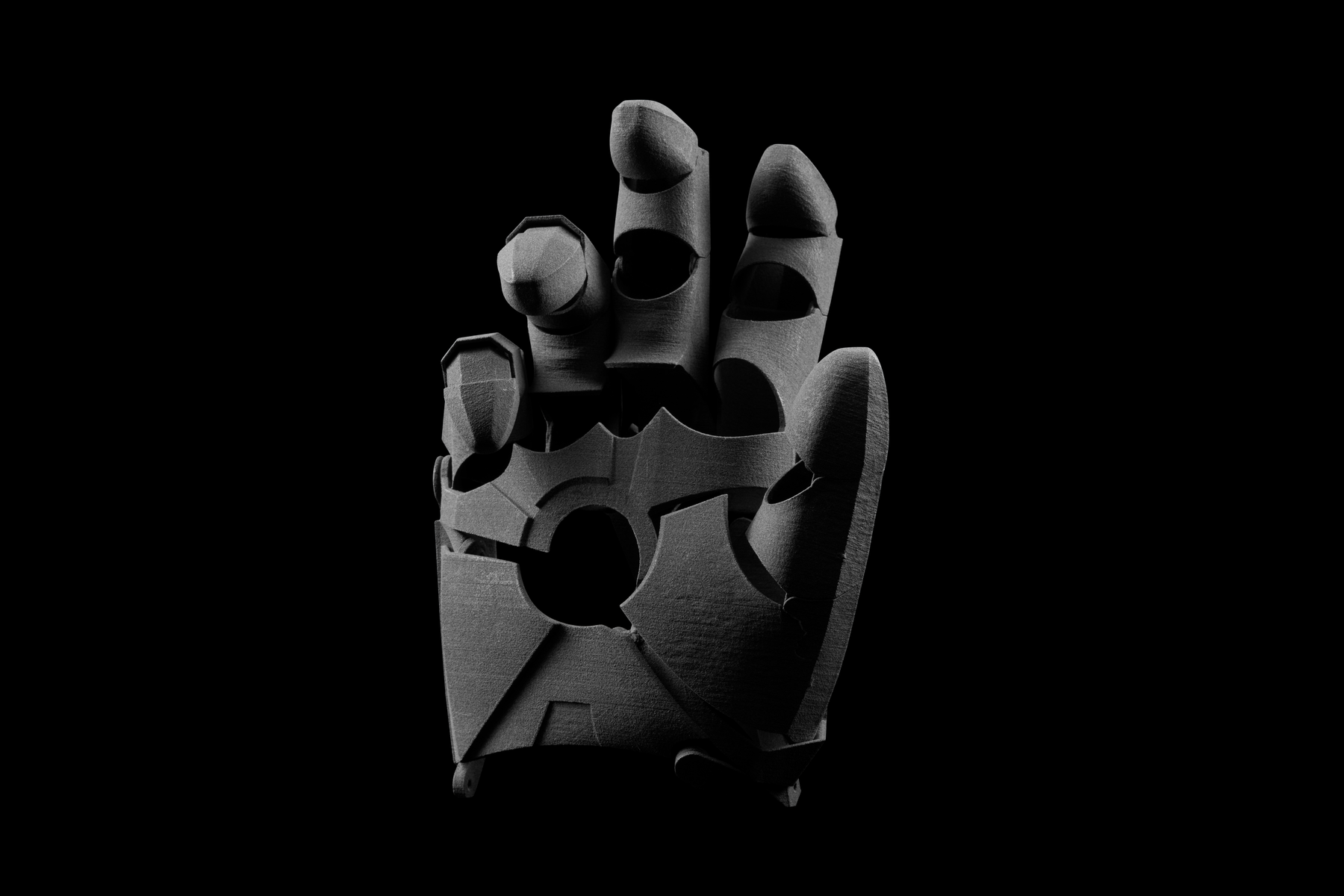

Bring production-ready nylon 3D printing onto your benchtop with an affordable, compact selective laser sintering (SLS) platform. The Fuse 1 delivers industrial power in a small footprint with effective powder containment and easy setup. From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process.

With final parts that combine strength, flexibility, and detail, Fuse 1 prints are ready for rigorous functional testing, or to ship ready-to-use products to customers.

Fuse 1 Build Volume: 165 × 165 × 300 mm (W x D x H).

Choose a Fuse 1 Printer Package

Each Fuse 1 selective laser sintering (SLS) 3D printer includes the essential tools required to start printing.

The Fuse 1 Basic Package Includes

- 1 Fuse 1 3D Printer

- 1 Build Chamber

- 1 Optical Cleaning Kit

- PreForm Software

The Fuse 1 Workflow Essentials Package Includes

- Everything is the Basic Package

- Fuse 1 Printer Stand

- Fuse Sift

- Fuse 1 Powder Cartridge

- Nylon 12 6kg x 3 (18kg)

The Fuse 1 High Efficiency Package Includes

- Everything is the Basic Package

- Fuse 1 Printer Stand

- Extra Fuse 1 Build Chamber

- Fuse Sift

- Fuse 1 Powder Cartridges x 2

- Nylon 12 6kg x 4 (24kg)

The Fuse 1 Max Throughput Package Includes

- Everything in the Basic Package x 2

- Extra Fuse 1 Build Chamber x 2

- Fuse 1 Printer Stand x 2

- Fuse Sift x 2

- Fuse 1 Powder Cartridge x 4

- Nylon 12 6kg x 10 (60kg)

Fuse 1 and Fuse Sift Standard Service, 1 / 2 / 3 / 5 Years

Our Fuse 1 and Fuse Sift Service Plans provide seamless delivery, training, and support from Formlabs 3D printing experts. Formlabs Services Teams have helped tens of thousands of customers 3D print successfully.

All Fuse / Fuse Sift purchases require 1, 2, 3 or 5 years service.

The Standard Service Plan includes:

- Priority phone and email support

- Annual preventative checkups

- Remote training

- Renewable coverage

- Worry-free warranty

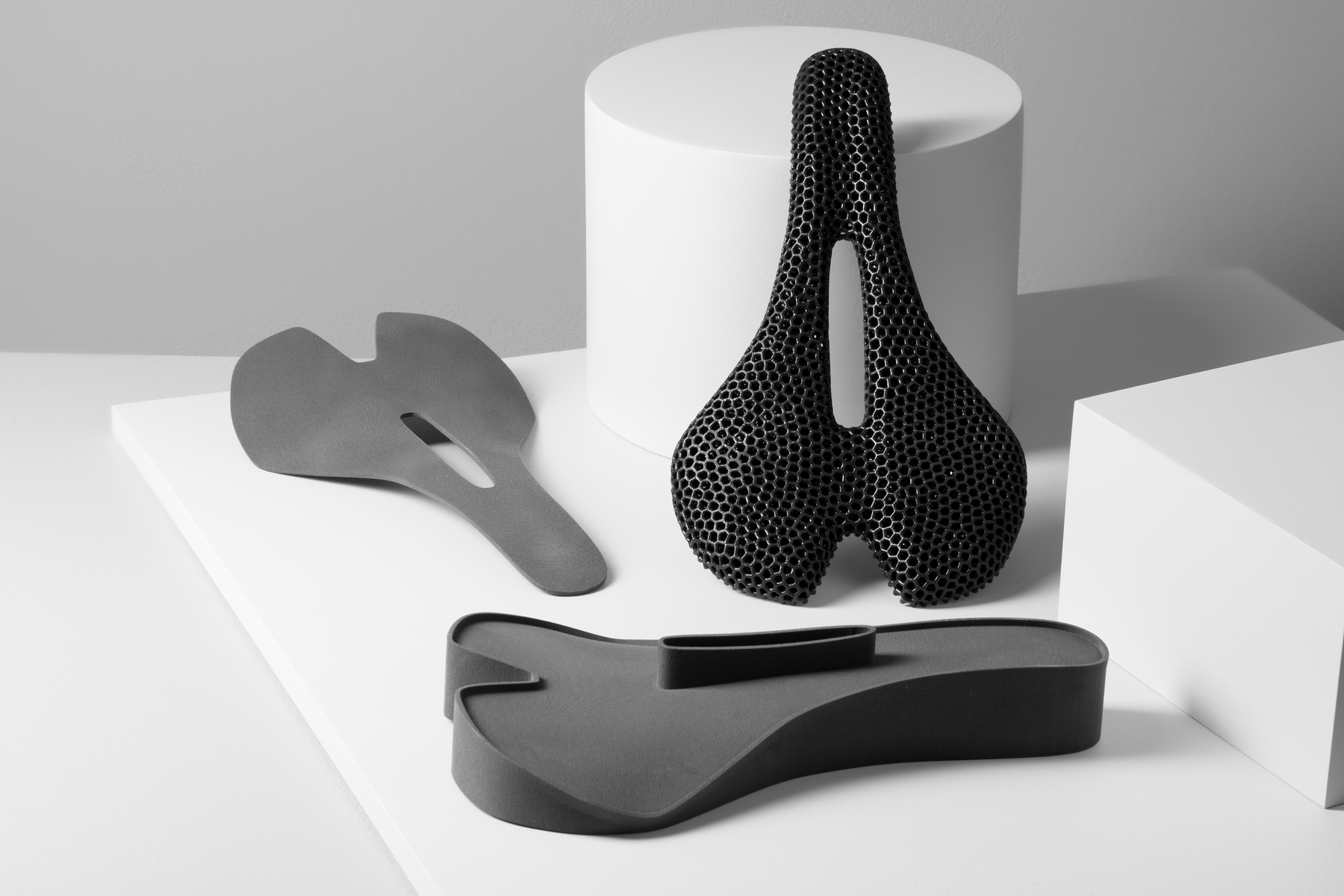

The Next Generation of Industrial 3D Printing

Bring industrial-quality prototyping and production in-house with affordable, professional SLA and SLS 3D printers.

Materials

Formlabs extensive library of general purpose and specialty 3D printing materials designed for everything from early concepting to functional prototyping to end-use production.

Post-Processing

Fuse Sift make post-processing easy, so you can consistently produce quality results and maintain a tidy workspace with less time and effort.

Fuse 1 Accessories

Stock up on accessories to ensure printing uptime and increase your throughput.

Fuse 1 Build Chamber 230V

Reduce downtime by transferring modular build chambers and powder cartridges between the Fuse 1 and Fuse Sift for a nonstop, cyclical workflow.

Each Fuse 1 includes one build chamber, compatible with the Fuse 1 and Fuse Sift. Keeping an extra build chamber in your toolkit allows you to run a new print as soon as a previous job is completed.

Fuse 1 Printer Stand

This steel stand raises the Fuse 1 to an ergonomic height.

Industrial Vacuum 230V

The Fuse Sift powder recovery station incorporates an external vacuum, sold separately, to help you efficiently, safely maintain a clean workspace.

Due to potential hazards associated with powders, a static dissipative vacuum that is NFPA 652 compliant is required. This Class II Division 2 vacuum fulfills all safety requirements for the Fuse Sift.

Fuse 1 Powder Cartridge

Reduce downtime by transferring modular powder cartridges and build chambers between the Fuse 1 and Fuse Sift for a nonstop, cyclical workflow.

Use the powder cartridge to load material dispensed from the Fuse Sift into the Fuse 1 hopper. The powder cartridge is also used as a mixing vessel when combining fresh and used powder.

Fuse 1 Replacement Exhaust Air Filter

The Fuse 1 uses an exhaust filter to remove sintering byproducts from its exhaust.

Fuse 1 Replacement Intake Air Filter

The Fuse 1 uses an intake filter to remove potential contaminants from air being drawn into the printer.

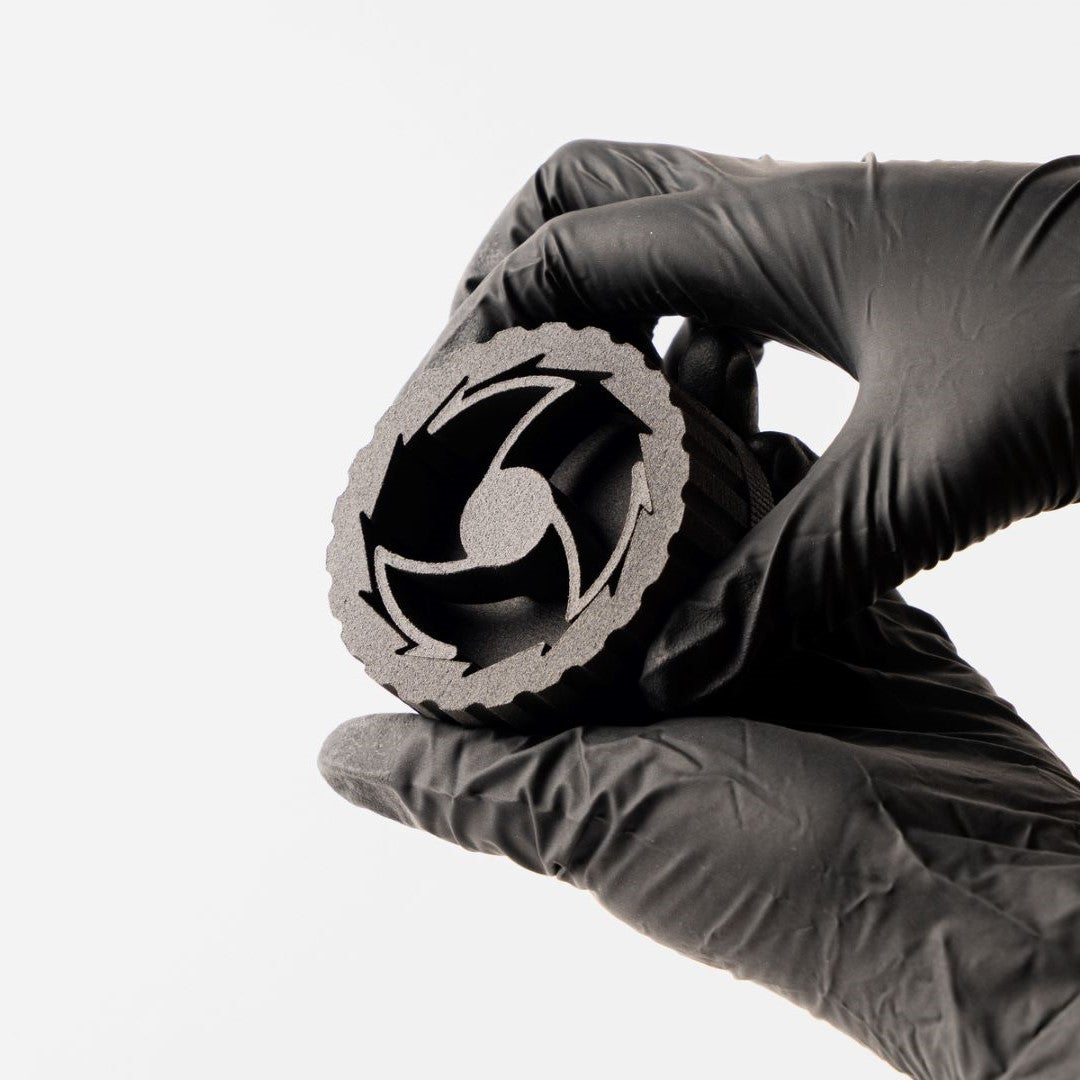

Fuse 1 Optical Cassette

All SLS printers require operators to clean the optics before every print, which often involves disassembling complex systems. The Fuse 1 protects its optics with an optical cassette designed for tool-free removal and installation.

Each Fuse 1 includes two optical cassettes, so you can seamlessly swap a used cassette out for a clean one to quickly start another print.

Fuse Sift 150 Sieve

During part extraction on the Fuse Sift, unsintered powder is dislodged and funneled into the sifter below the workspace. This sieve filters out any small chunks or debris to keep the powder clean. The reclaimed powder can then be stored in a dedicated hopper until mixing with fresh powder for the next print.

Fuse Sift HEPA Air Filter

A HEPA filter is used in conjunction with the Fuse Sift air handling system to filter out powder. This enables the Fuse Sift to maintain negative pressure under the hood and minimizes potential mess in the workspace.

About Us

3D Printers Perth is a Perth supplier of high-quality 3D printers and materials, working directly with leading brands like Formlabs to support Australia’s additive manufacturing needs. Backed by over 30 years of experience through Afaridan Plastics and Adarsh Australia, we bring trusted expertise in 3D printing to organisations across Australia.

Our clients span universities, manufacturers, dental clinics, health organisations, jewellery, aerospace, mining, defence, and other industries across Perth and wider Australia.