Common Questions

What is the Difference Between SLA and SLS Materials?

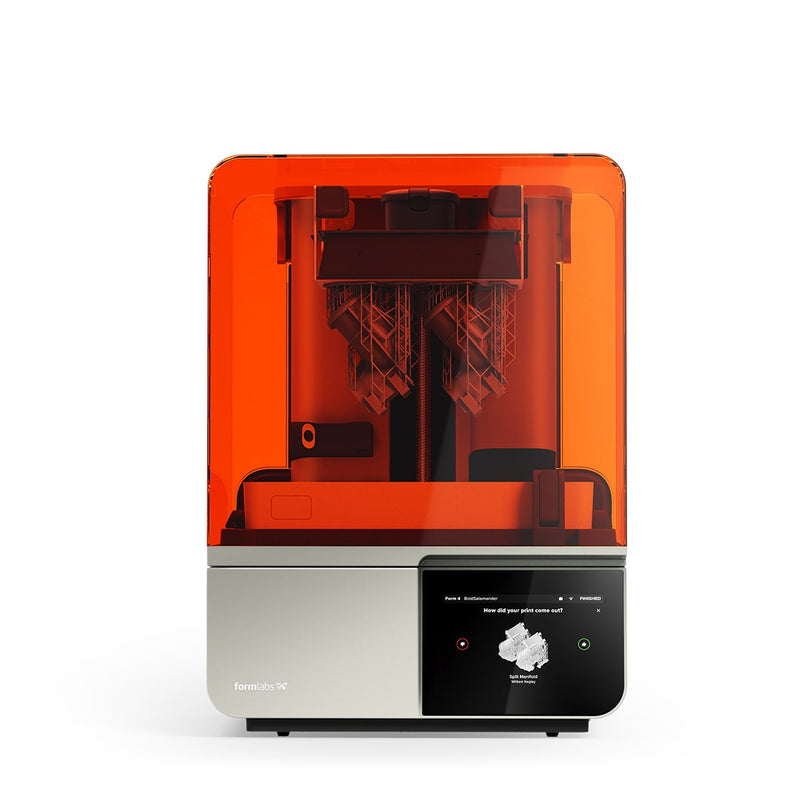

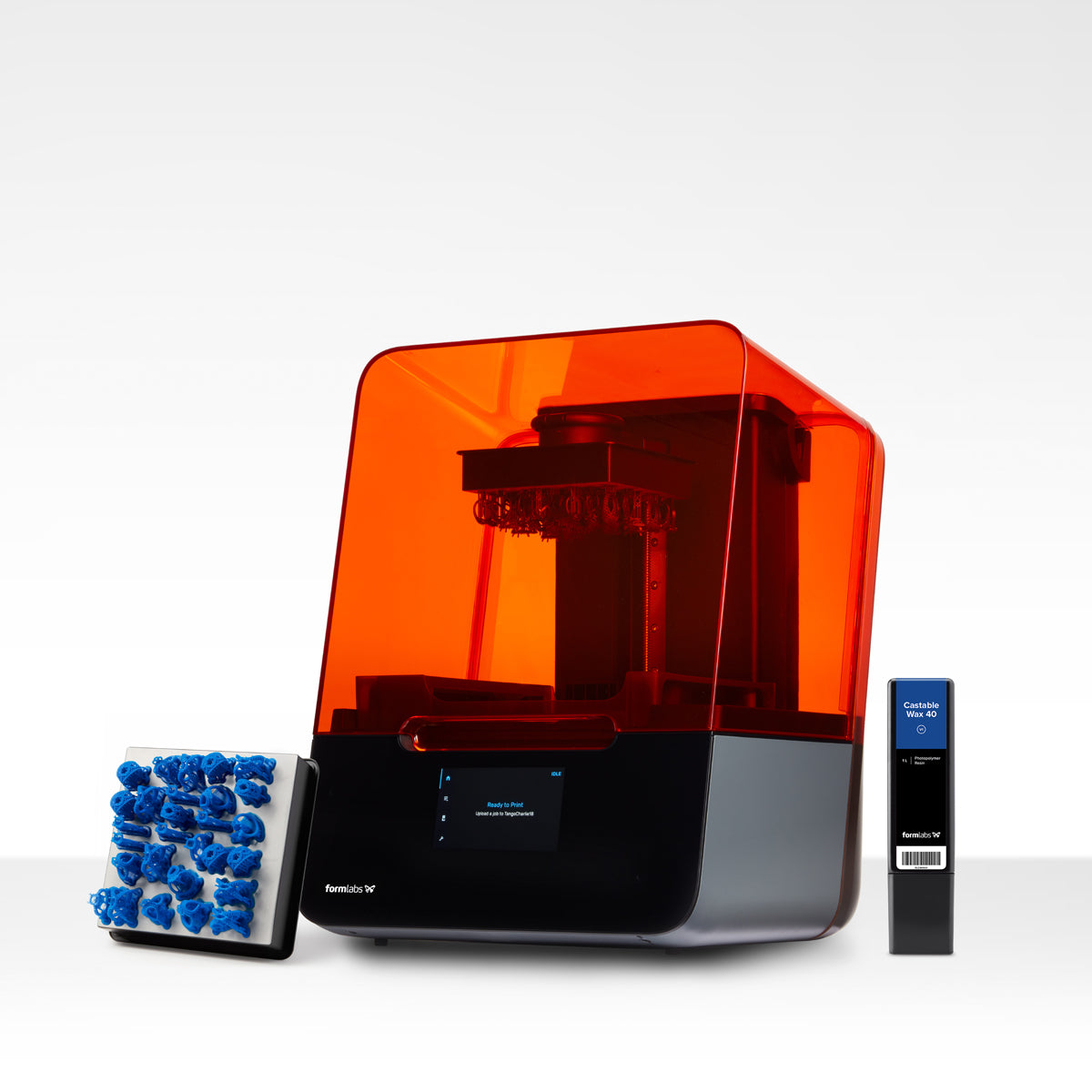

Formlabs currently has two 3D printer technologies on the market: SLA and SLS.

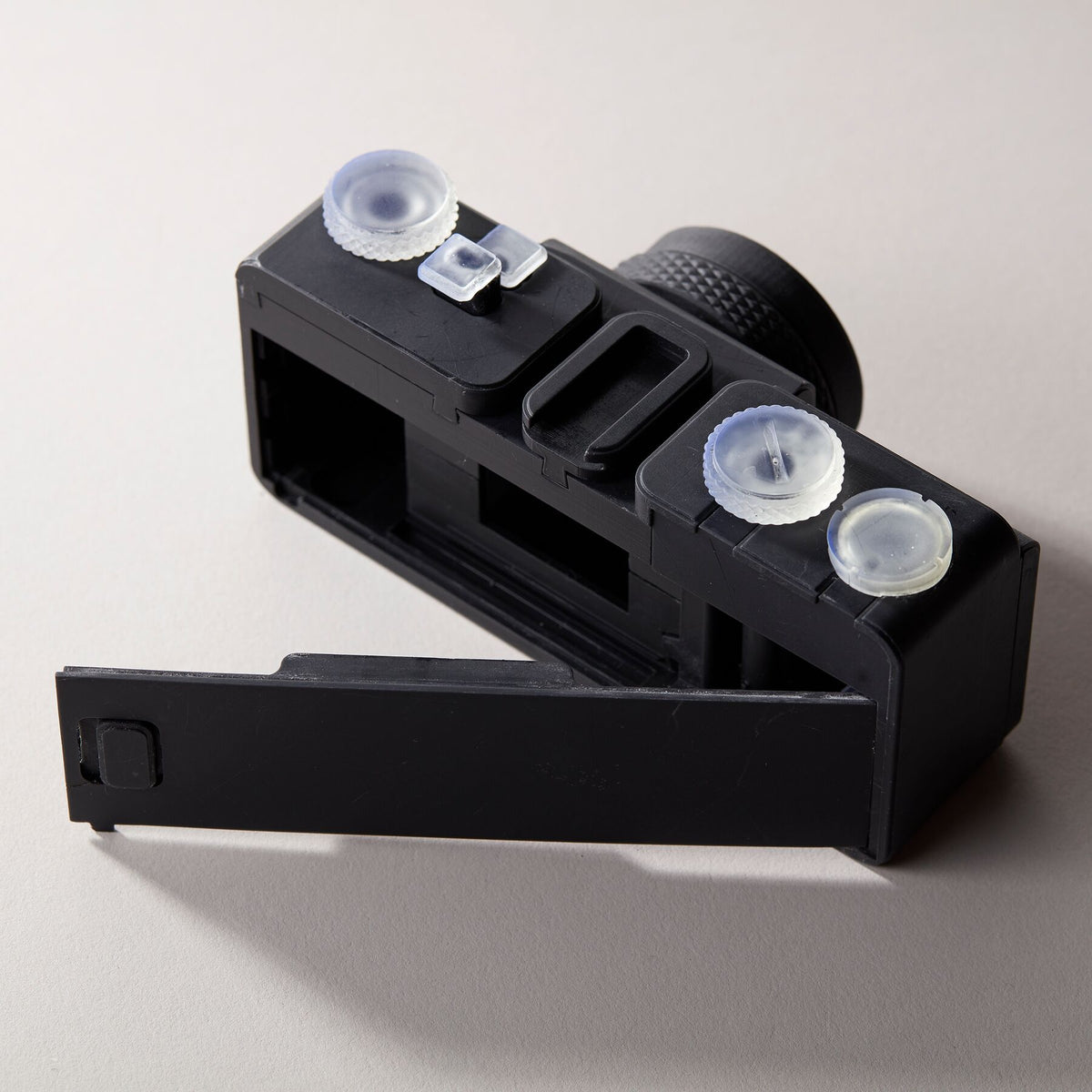

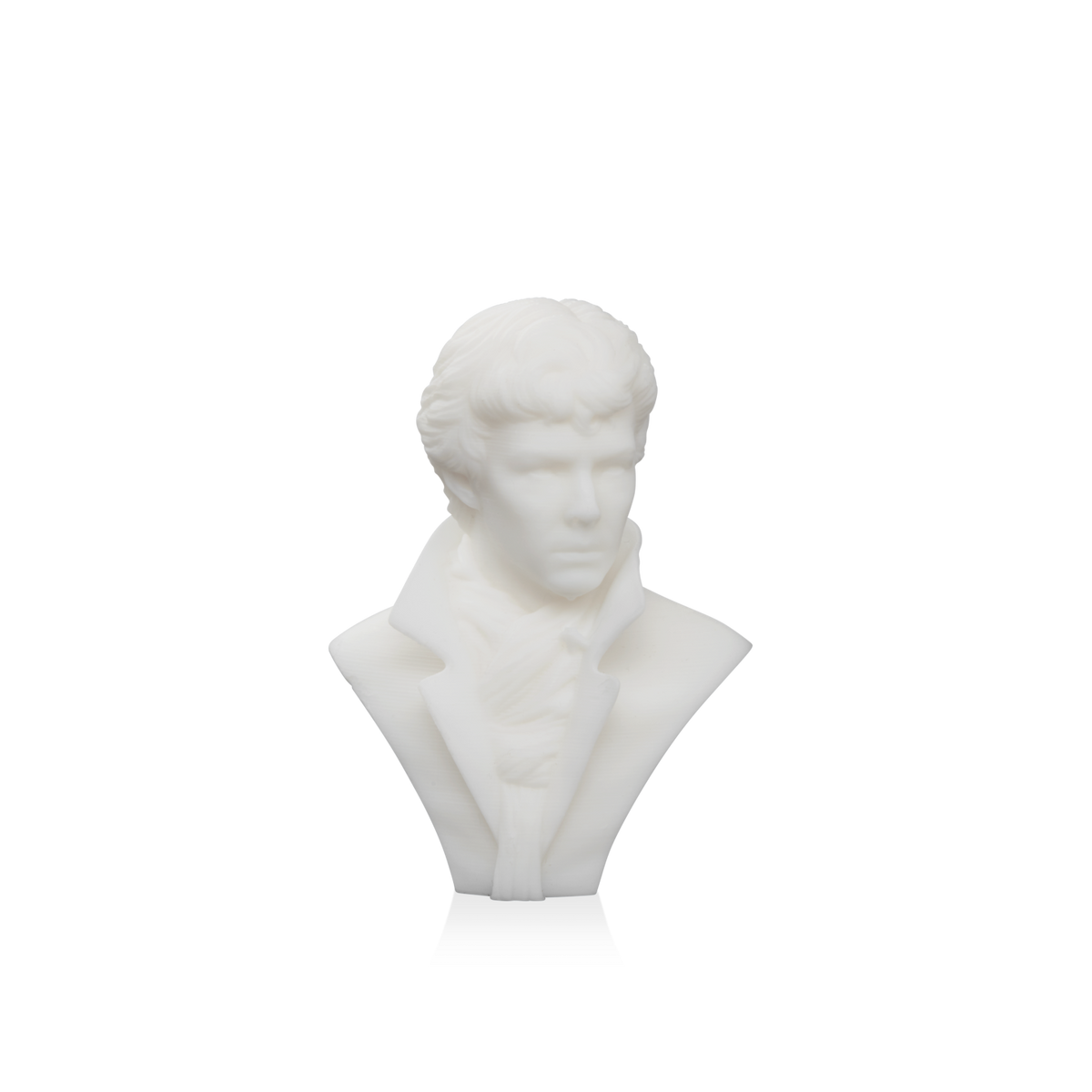

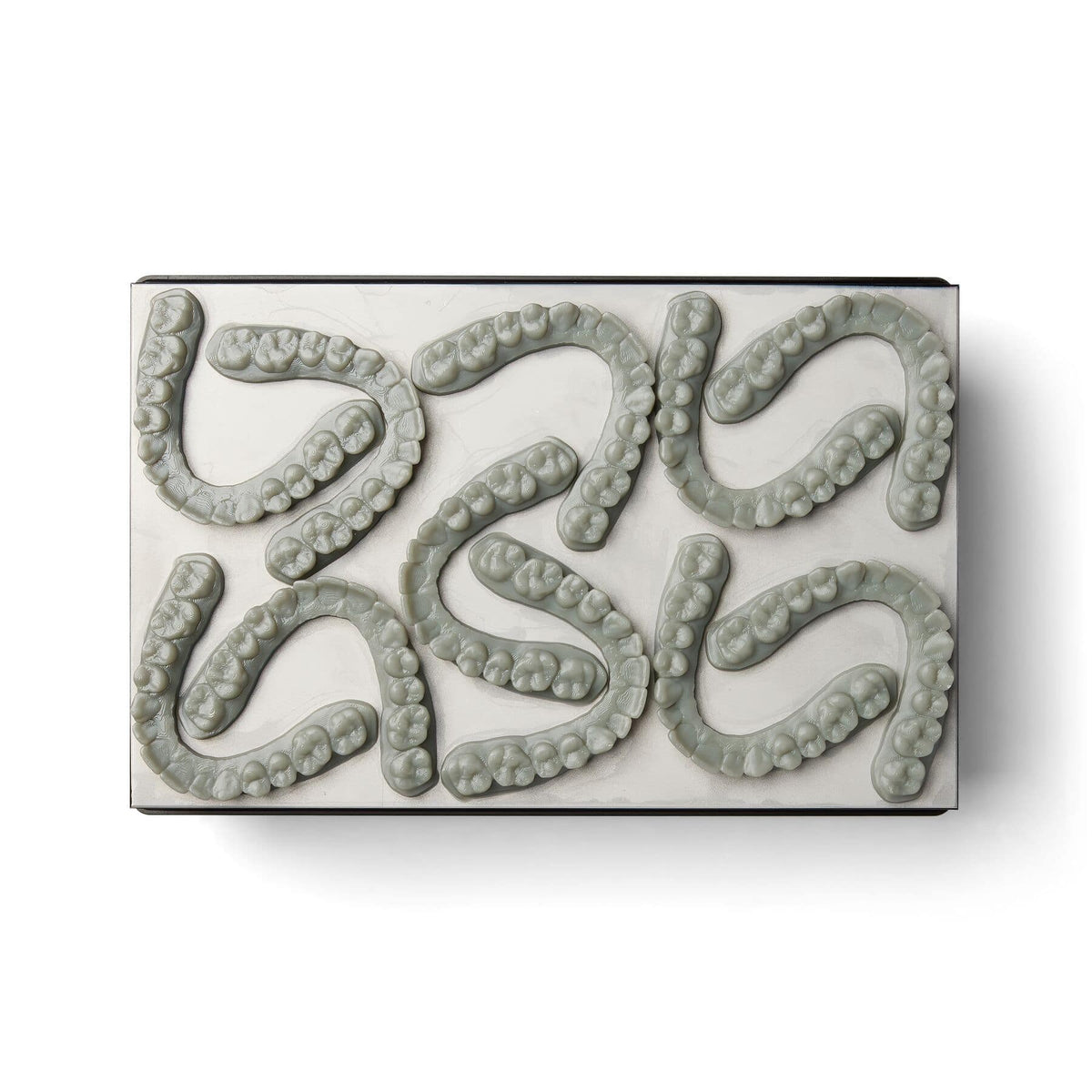

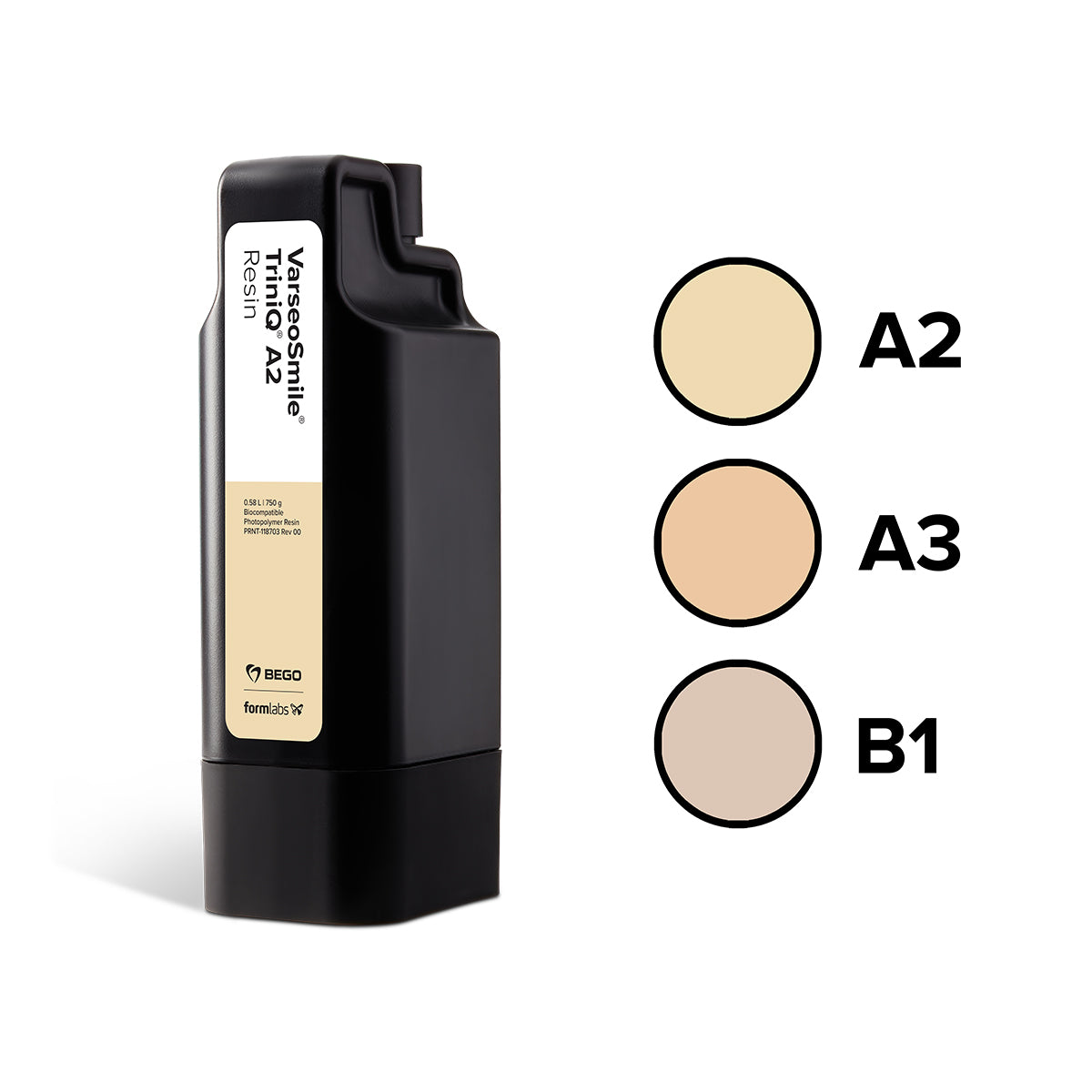

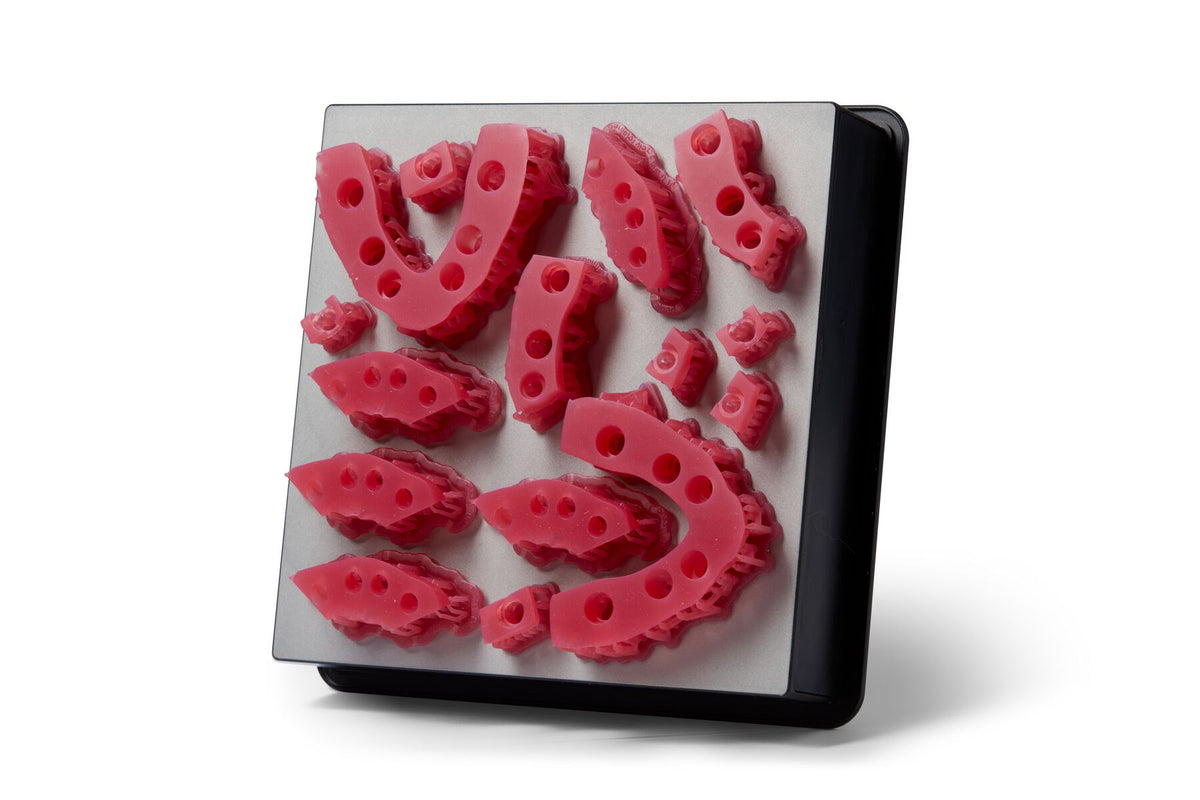

For each 3D printer technology there is a corresponding material science; SLA 3D printers use resins, while SLS 3D printers use nylon powder.

For Formlabs 3D printers, resins are used for the Form lineup. This means Form 3+ / Form 3B+ and Form 3L / Form 3BL use resins materials for their 3D printing.

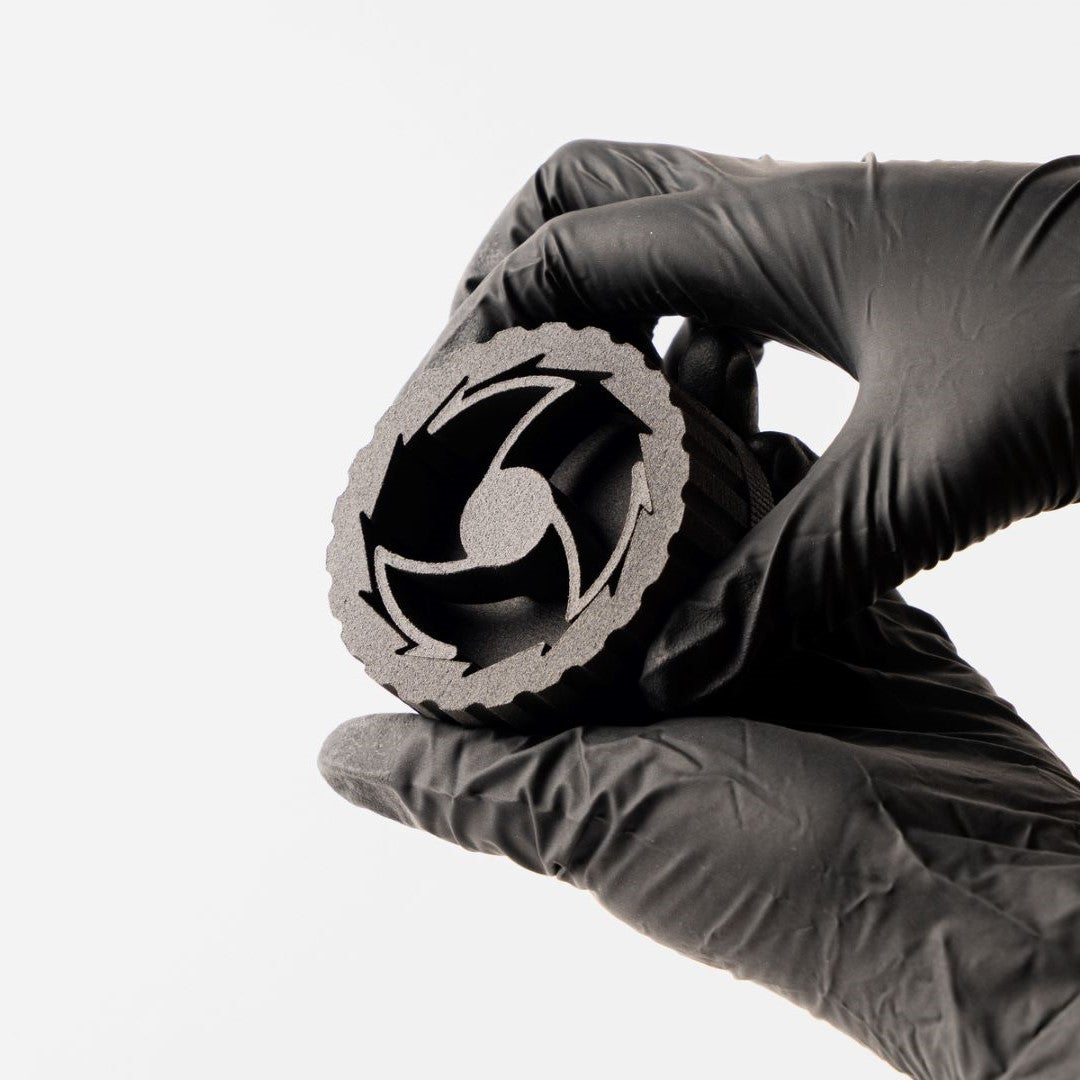

On the other hand, nylon powders are used for Formlabs Fuse 3D printers. This currently includes the Fuse 1 and Fuse 1+ 30W.

How Does Each 3D Printing Technology Work?

SLA 3D printers cure resin with laser(s) to harden each layer of a print. SLS 3D printers also work in layers but instead use laser(s) to sinter (or "Fuse") each layer of nylon powder.

Each technology has advantges for certain use-cases which we talk about more on the 3D Printers Collection Page.

All Formlabs SLA and SLS Materials

Browse all Formlabs 3D printing materials. Resins cartdridges can be used in SLA printers, while nylon powders can be used in SLS printers.