FDM vs SLA vs SLS 3D Printers

3D Printing Technologies Comparison: FDM vs SLA vs SLS

This article will go through the pros and cons of FDM vs SLA vs SLS 3D printers to help you decide which is best for your use-case.

Additive manufacturing, or 3D printing, can lower costs, save time, and allow for parts and products that couldn’t be made with traditional manufacturing methods. From concept models and functional prototypes, to end-use parts, 3D printing can be the best solutions for a wide variety of applications.

Over the last few years, high-resolution 3D printers have become more affordable, easier to use, and more reliable. As a result, 3D printing technology is now accessible to more businesses and even hobbyists, but choosing the “best” 3D printing technology can be challenging.

Which solution is best for you and your application? What materials are available for each technology? What equipment and training do you need? How expensive will the printers and ongoing costs be?

On this page, we’ll explain the three most common (plastic) 3D printing processes: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

In summary:

FDM extrudes melted filament layer by layer onto a bed and is often used by hobbyists. Meanwhile, SLA uses a light to cure UV sensitive resin layer by layer and ranges from hobbyist to industrial grade.

Lastly, SLS sinters powder without needing support structures and is primarily used by industry to 3D print mechanically strong parts.

If you prefer to speak to an expert, consider contacting the 3D Printers Perth team.

Fused Deposition Modeling (FDM)

Fused deposition modeling (FDM), otherwise known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer/hobbyist level. FDM 3D printers build parts by melting and extruding filament through the printer’s nozzle, depositing layers onto the build plate.

FDM works with a range of thermoplastics, including ABS, PLA, PETG, and more. The technology is well-suited for simple proof-of-concepts and low-cost prototyping of simple parts.

FDM parts are cheap to make but often have visible layer lines and inaccuracies in complex designs. Consider a FDM 3D printer if you are just getting into 3D printing for home use or if you're looking for commercial grade printers.

FDM, especially hobbyist-grade printers, have relatively low resolution and accuracy when compared to SLA or SLS, and is not the best option for printing complex or intricate designs or parts. Chemical and mechanical polishing processes can produce higher-quality finishes compared to standard FDM prints. Industrial FDM 3D printers may use soluble supports to mitigate some of these issues and offer a wider range of thermoplastics, but are also much more expensive.

3D Printer Perth retail UltiMaker 3D printers.

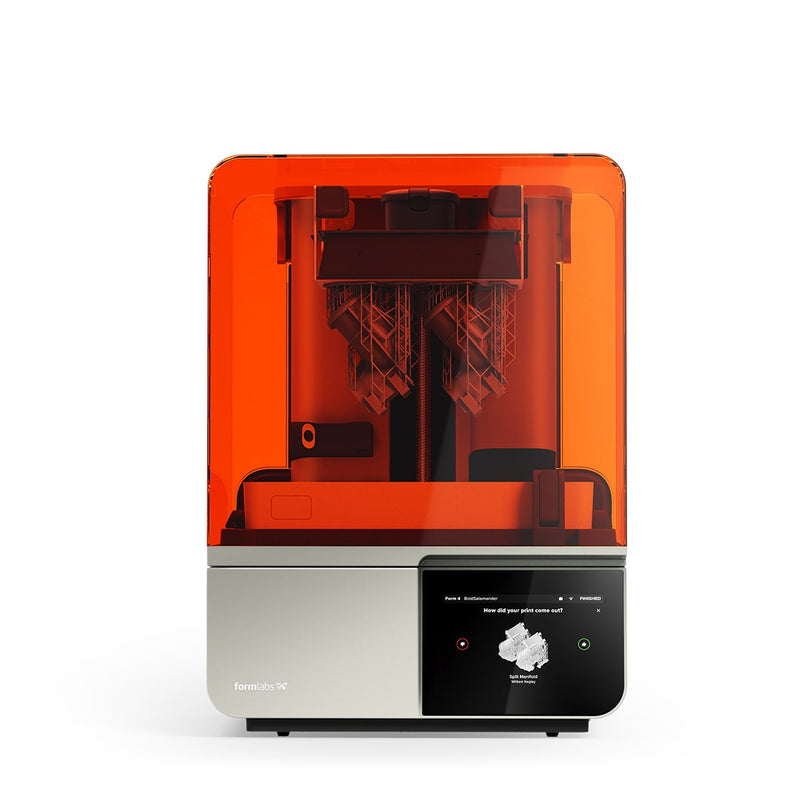

Stereolithography (SLA)

Stereolithography was invented in the 1980’s, making it one of the most established 3D printing technologies. SLA 3D printers are still one of the most popular technologies for professionals and commercial use. SLA 3D printers use a laser to cure UV sensitive liquid resin into hardened plastic layer by layer.

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies, but the main benefit of SLA lies in its versatility. There are a large number of material options which each have their own optical, mechanical, and thermal properties. Many materials are used to match traditional standard, engineering, and industrial thermoplastics.

SLA parts have clean edges, a smooth surface finish, and minimal visible layer lines but are more expensive per part. Consider SLA 3D printers if you need prototype or end-use parts that are strong and have a smooth surface finish.

SLA 3D printing is a great option for highly detailed prototypes requiring smooth surfaces. This includes but is not limited to molds, patterns, and functional parts. SLA is used in many industries, from engineering, product design, and manufacturing, to medical, dentistry, jewellery, model making, and education.

3D Printers Perth retailer Formlabs SLA 3D printers.

Selective Laser Sintering (SLS)

Selective Laser Sintering is one of the most common additive manufacturing technologies for commercial, industrial-grade applications. The technology is used and trusted by engineers and manufacturers for its parts’ strong mechanical properties, making it great for end-use parts.

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for supports. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts, making them perfect for final functional prototypes and end-use parts.

SLS parts have a slightly rough surface finish, but have almost no visible layer lines, and are strong and cost-effective. Consider SLS 3D printers if you need prototyped or end-use parts that are very strong.

The most common powdered material for Selective Laser Sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt. TPU 90A is also now available.

The combination of low cost per part, high productivity, and established materials make SLS a popular choice among engineers for functional prototyping, and a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

3D Printer Perth retail Formlabs' Fuse SLS 3D Printer.

What is the Difference Between FDM, SLA, and SLS 3D Printing?

Each type of 3D printer has its own strengths, weaknesses, and needs, and is suitable for different use cases.

|

Fused Deposition Modelling (FDM) |

Stereolithography (SLA) |

Selective Laser Sintering (SLS) |

|

|

Resolution |

3 out of 5 |

5 out of 5 |

4 out of 5 |

|

Accuracy |

4 out of 5 |

5 out of 5 |

5 out of 5 |

|

Surface Finish |

2 out of 5 |

5 out of 5 |

4 out of 5 |

|

Throughput |

4 out of 5 |

4 out of 5 |

5 out of 5 |

|

Complex Designs |

3 out of 5 |

4 out of 5 |

5 out of 5 |

|

Ease of Use |

5 out of 5 |

4 out of 5 |

4 out of 5 |

|

Pros |

Fast Low-cost consumer machines and materials |

High accuracy Smooth surface finish Large range of functional applications |

Strong, functional parts Design freedom No need for support structures |

|

Cons |

Low accuracy Low details Limited design compatibility |

Sensitive to long exposure to UV light Not best for outdoor use in direct sunlight |

Rough surface finish Limited but expanding material options |

|

Applications |

Low-cost rapid prototyping Basic proof-of-concept models |

Functional prototyping, molds and tooling, medical and dental, jewellery, and model making |

Functional prototyping Short-medium run manufacturing |

|

Print Volume |

Can be up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) |

Can be up to 353 x 196 x 350mm (desktop and benchtop 3D printers) |

Can be up to 165 x 165 x 300 mm (benchtop industrial 3D printers) |

|

Materials |

Standard thermoplastics, such as ABS, PLA, etc. |

A huge variety of resins for engineering, jewellery, entertainment, dental, medical, and general applications. |

Engineering thermoplastics. Nylon 11, Nylon 12, and their composites. TPU 90A |

|

Training |

Minor training for machine building, operation, and finishing; moderate maintenance training. |

Easy to set up. Minor training on, maintenance, machine operation, and finishing. |

Moderate training on machine operation, maintenance, and finishing. |

|

Facility Requirements |

Temperature controlled environment preferred. |

Office environments for desktop machines. |

Workshop environments for benchtop systems. |

|

Ancillary Equipment |

Support removal system for machines with soluble supports, finishing tools. |

Post-curing station, washing station (optionally automated), finishing tools. |

Post-processing station for part cleaning and material recovery. |

Source *Formlabs

Need some help deciding? Speak to our team today!

3D Printing Costs and Return on Investment With FDM, SLA, and SLS Technologies

There is no “best” 3D printing technology; each type of 3D printer has its own pros and cons. Therefore, you should choose the technology that makes the most sense for you and your business.

Prices have dropped significantly over the decades and in recent years, and all three technologies are now available in compact, affordable systems.

Importantly, calculating 3D printing costs must include upfront equipment costs as well as material and labour costs.

Detailed breakdown:

|

Fused Deposition Modelling (FDM) |

Stereolithography (SLA) |

Selective Laser Sintering (SLS) |

|

|

Equipment Costs |

Budget printers start at $300-1000. Higher quality desktop printers start around $3 000, and industrial systems are available from $20 000. |

Professional desktop printers start at $7 000 and large-format benchtop printers at $16 000. |

Benchtop industrial systems start at $60 000, increasing depending on needs. |

|

Material Costs |

$70-$180/kg for most standard and engineering filaments. $30/kg for hobbyist level filament. |

$130-$350/L for most standard and engineering resins. |

$150-250/kg for nylon and TPU. SLS requires no support structures, and unfused powder can be reused, which lowers material costs. |

|

Labour Needs |

Manual support removal (can be mostly automated for industrial systems). Lengthy post-processing is required for a high-quality finish. On-going maintenance needed. |

Washing and post-curing (both can be mostly automated). Simple post-processing to remove support marks. |

Cleaning to remove excess powder. Media blasting to improve the surface finish of parts. |

Find the best 3D printer for you by speaking with our 3D printer experts.