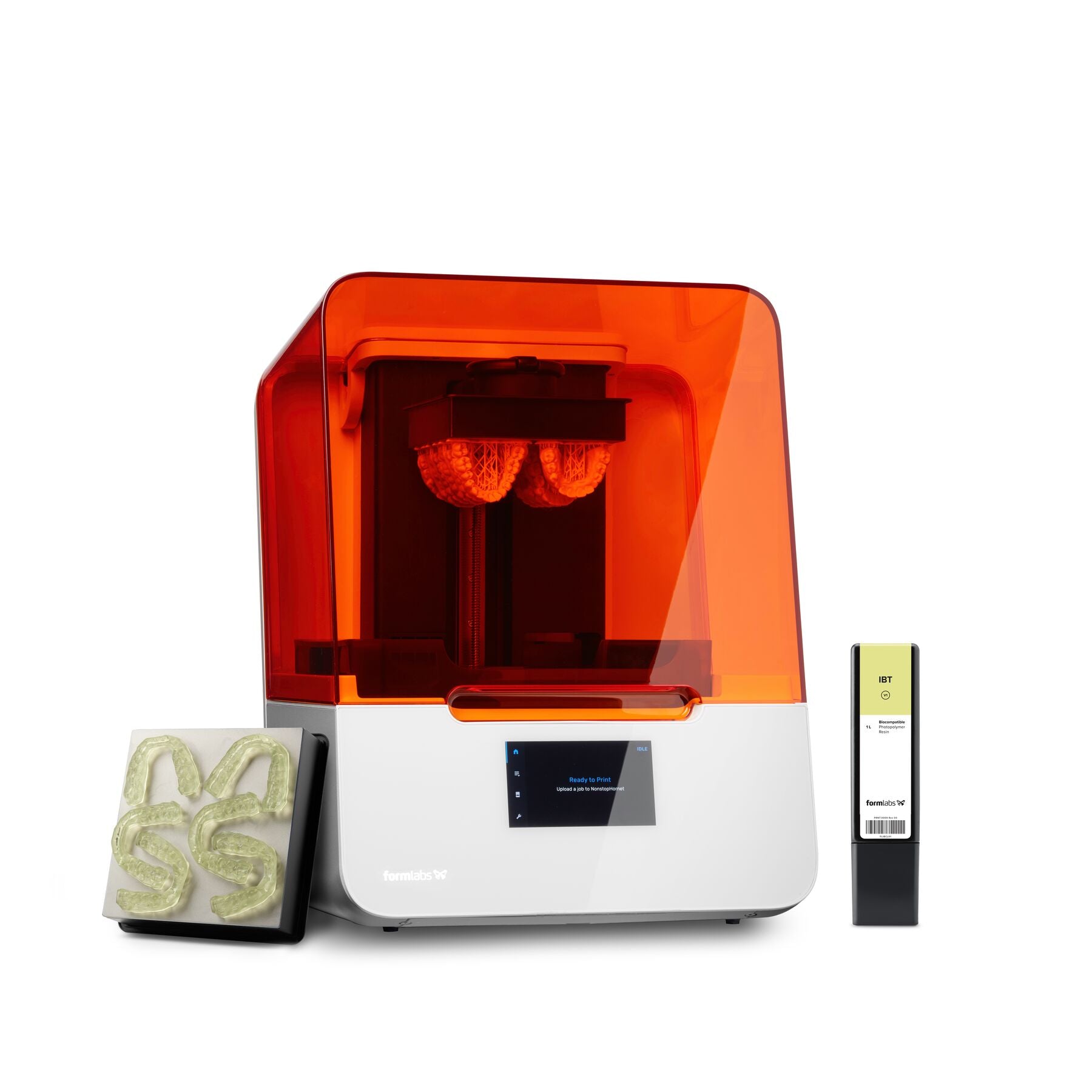

IBT Resin

Why Choose IBT Resin?

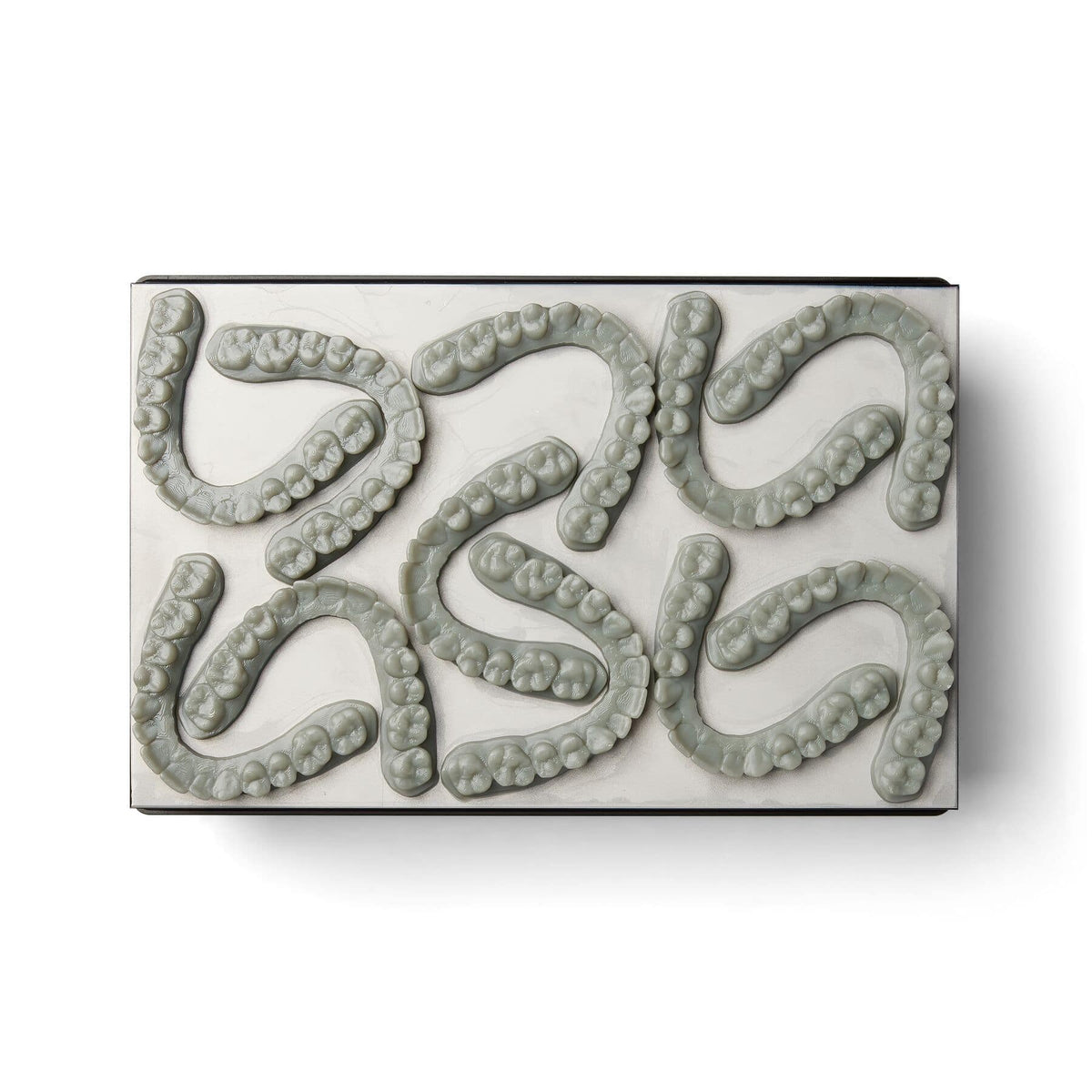

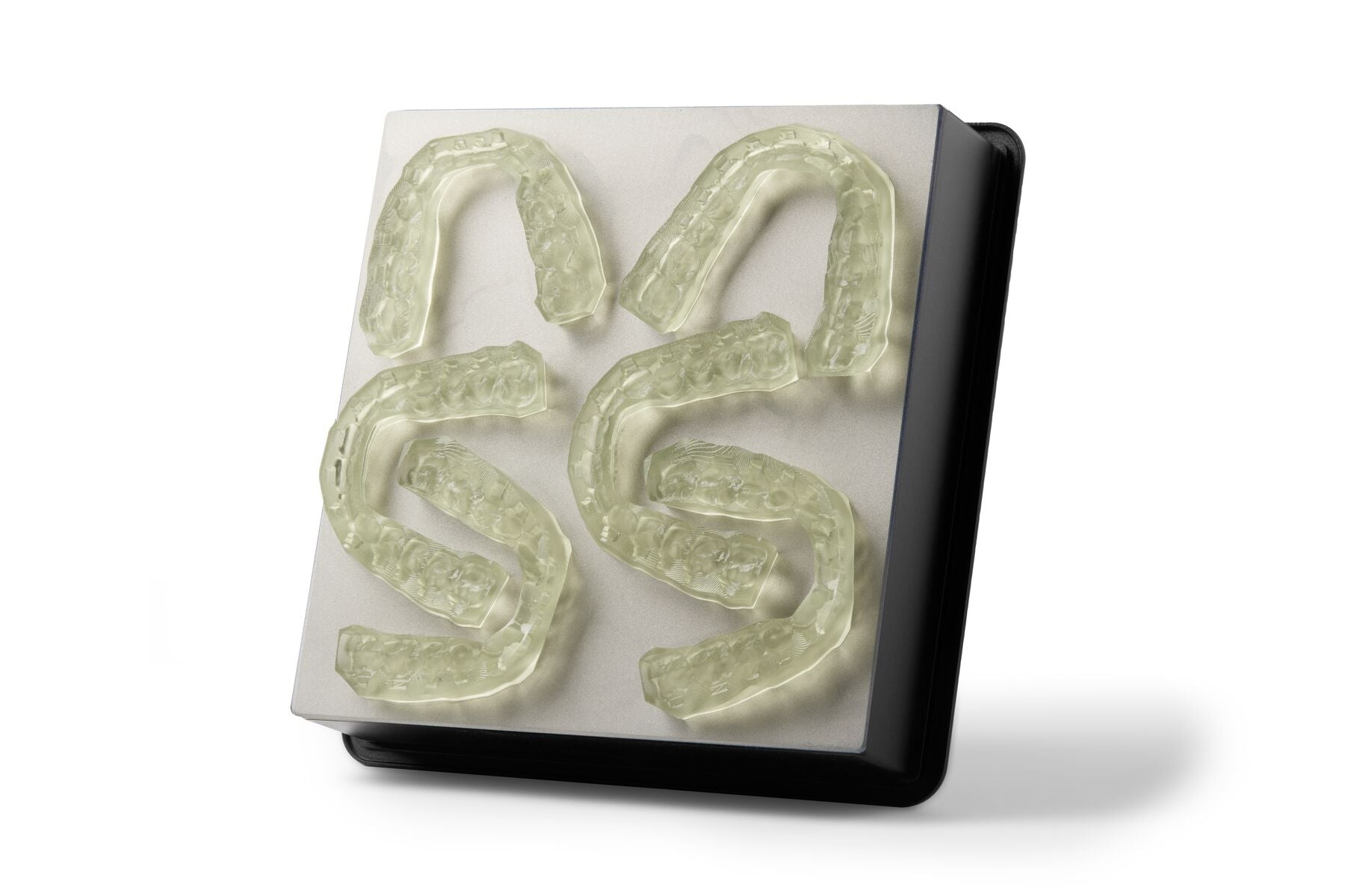

3D printed indirect bonding trays printed in IBT Resin reduce chair time and increase patient comfort by placing all of the brackets or entire quadrants at once.

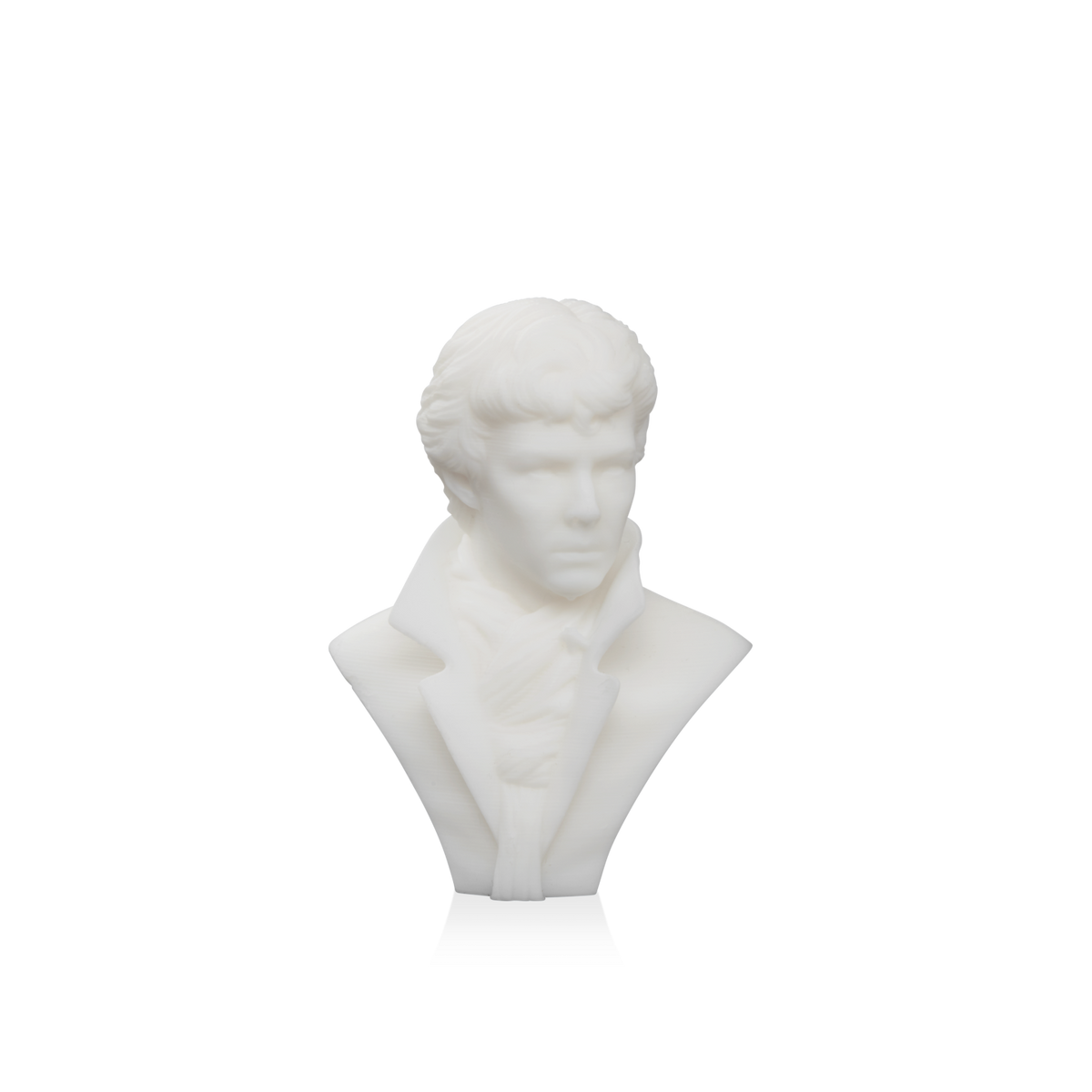

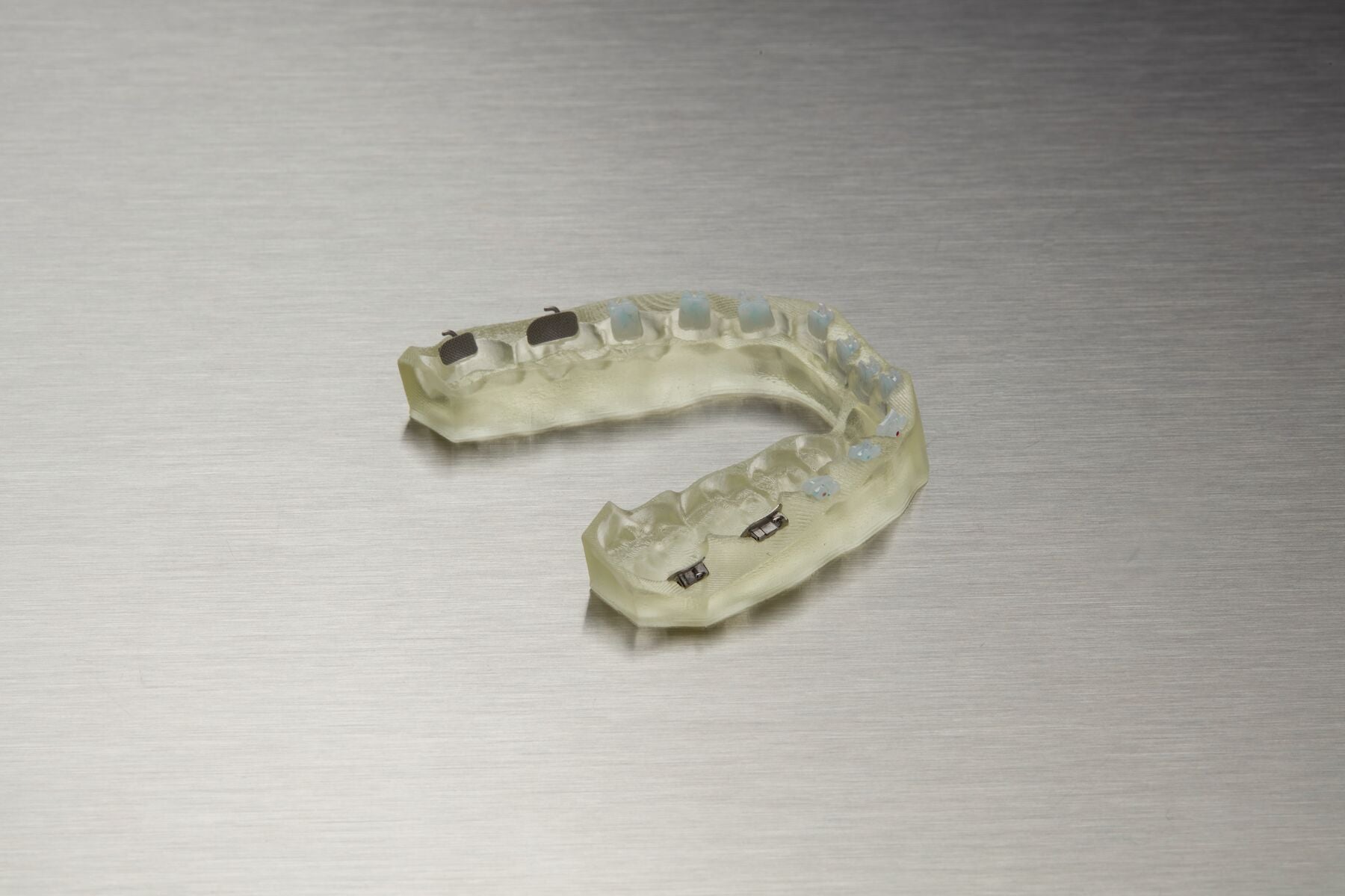

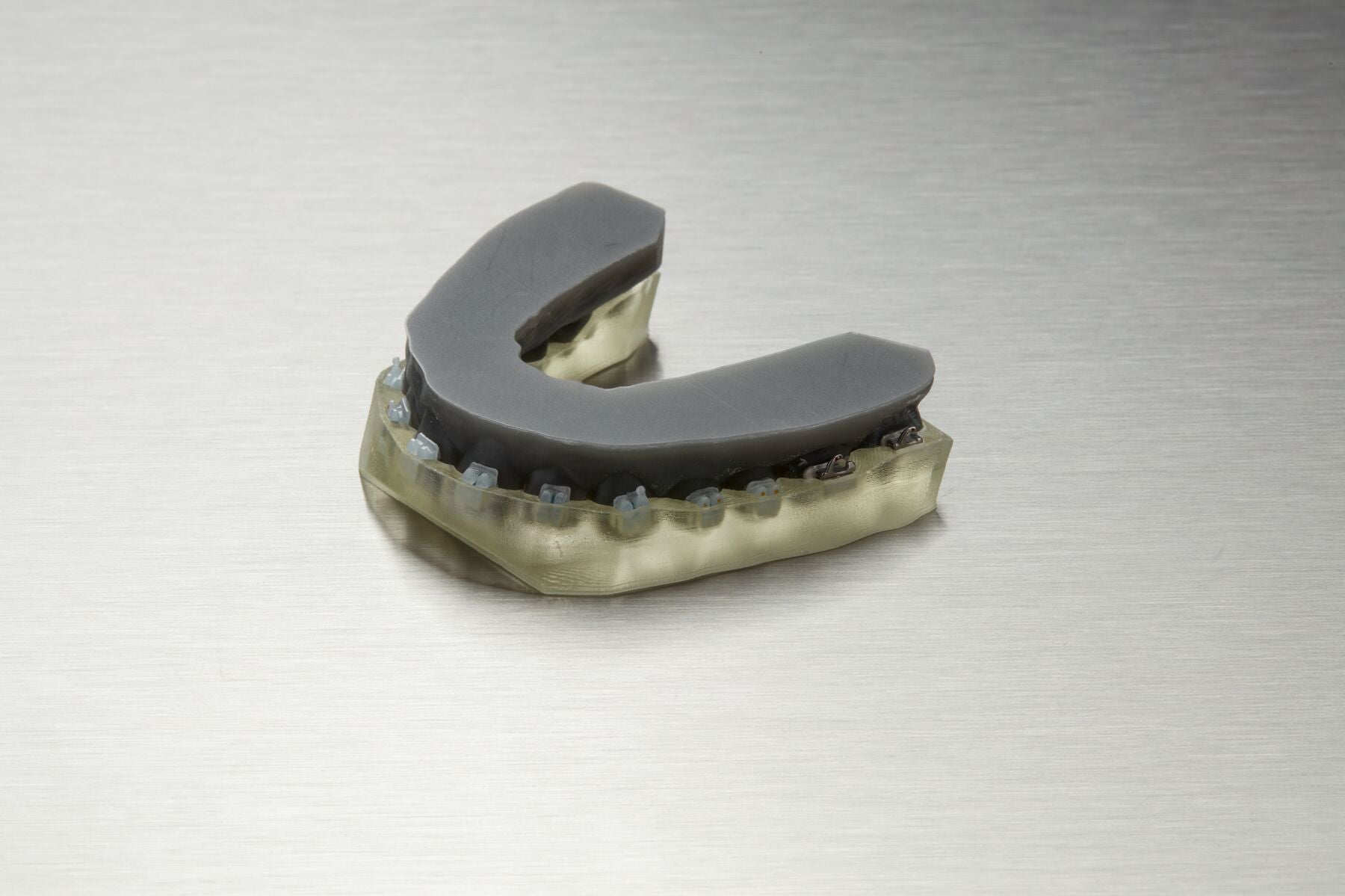

Ease of use and comfort

Soft, flexible 3D printed appliances are easy to work with and comfortable for the patient.

Optimized tear strength

Easy to remove from the mouth without moving brackets for accurate placement with less room for error.

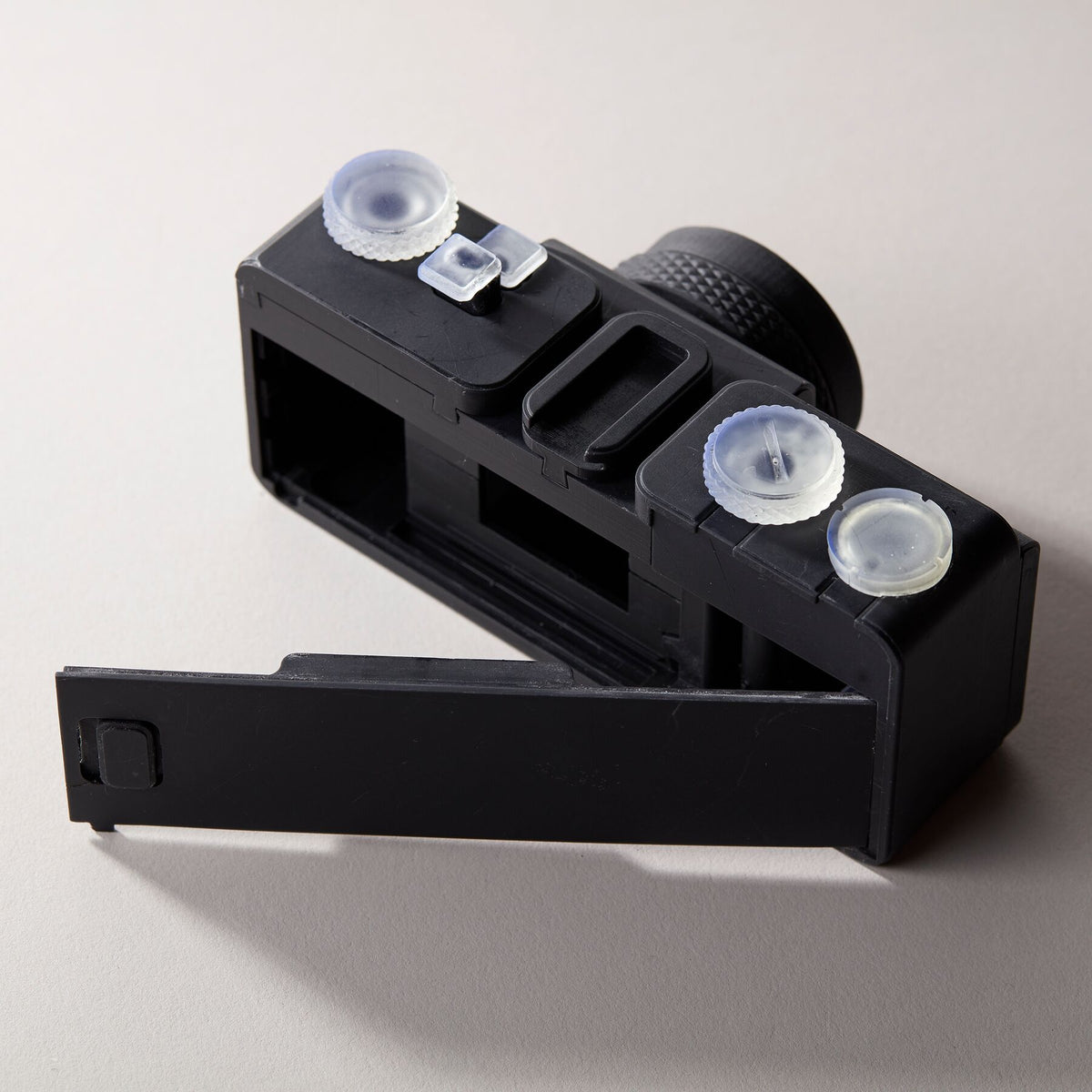

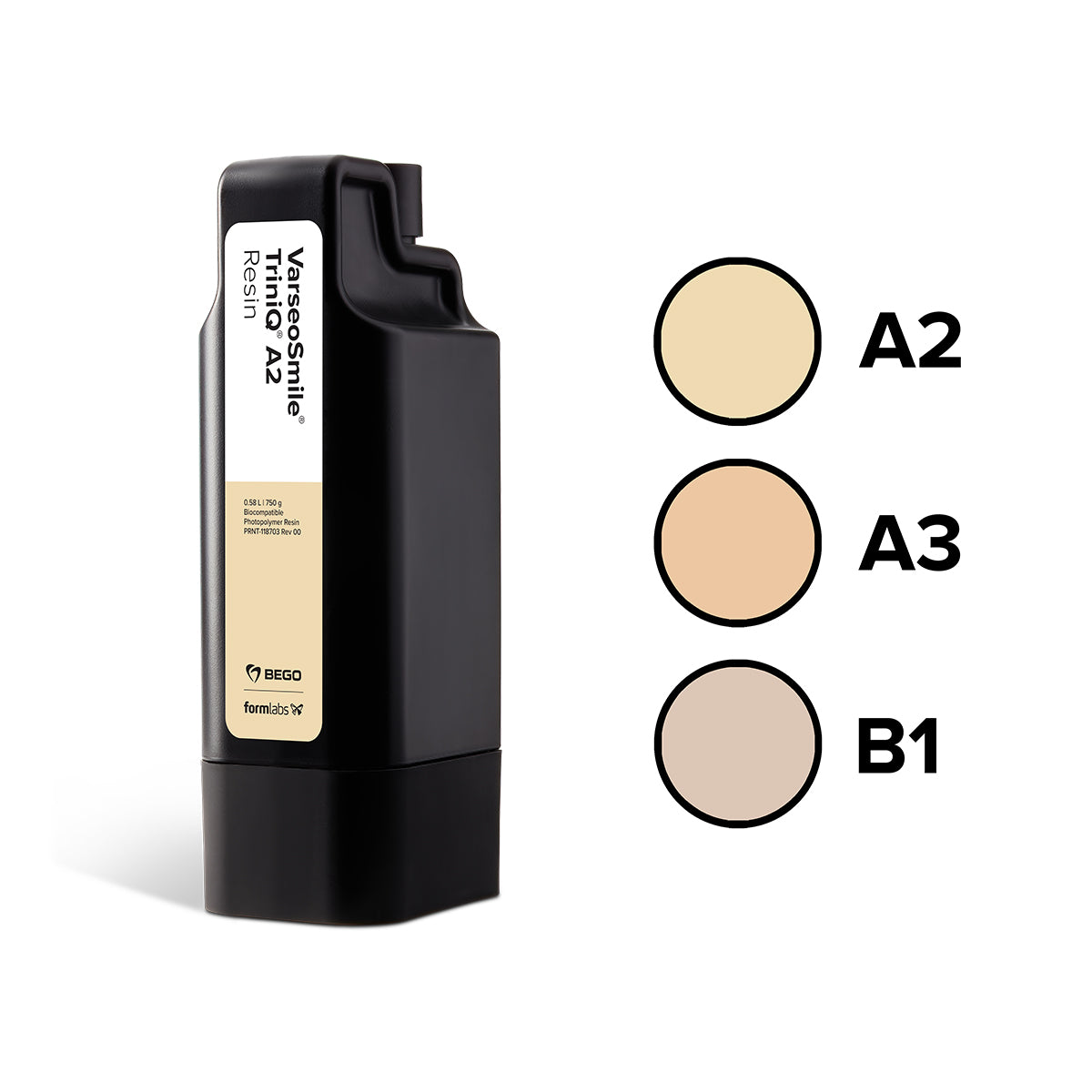

Better clinical visualization

Translucency allows for initial light-curing of all the brackets in one step, and yellow tint allows for higher contrast of brackets for better clinical visualization.

No-hassle post-processing

Automated Form Wash and Form Cure make rinsing and curing easy, with no need for glycerin or nitrogen post-curing.

Comparison: Traditional Bracket Placement & IBT Resin

Traditional Bracket Placement

● Brackets must be placed individually

● Orthodontist can be involved in many steps of the process

● Plan case using stone models, pen and paper

● Storage and mailing of physical models

Indirect Bonding Tray Bracket Placement

● Place all brackets in a single shot

● Assistants or laboratory can complete some steps to save orthodontist time

● Efficient, flexible digital workflow and case planning

● Easy to communicate, store, and send digital files

The Digital Workflow With IBT Resin

1. Scan

Scan the patient’s anatomy using a 3D intraoral scanner and X-ray or sometimes CBCT.

2. Plan & Design

Plan the case using your software of choice.

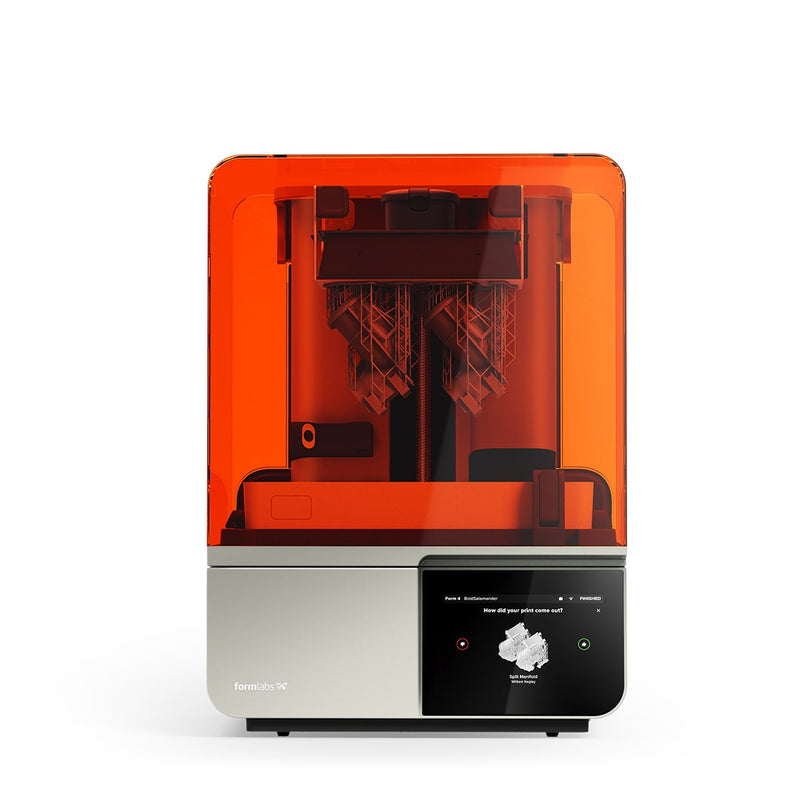

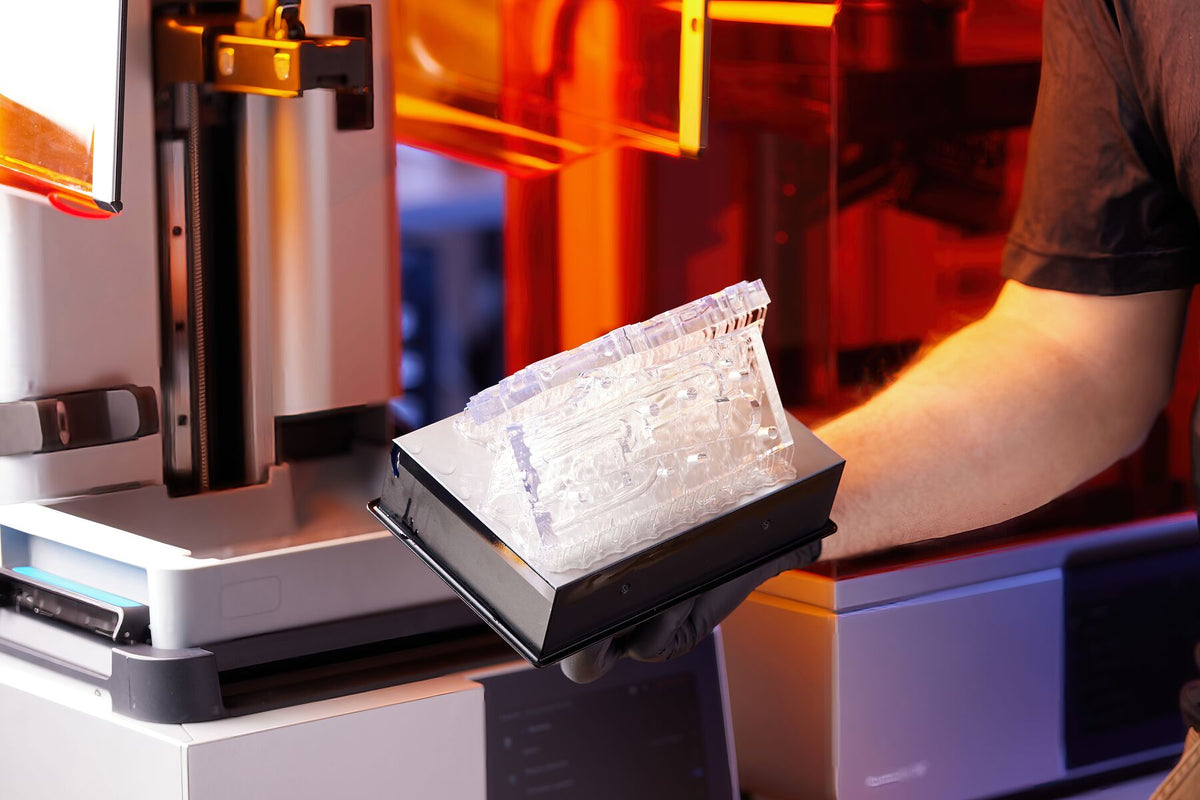

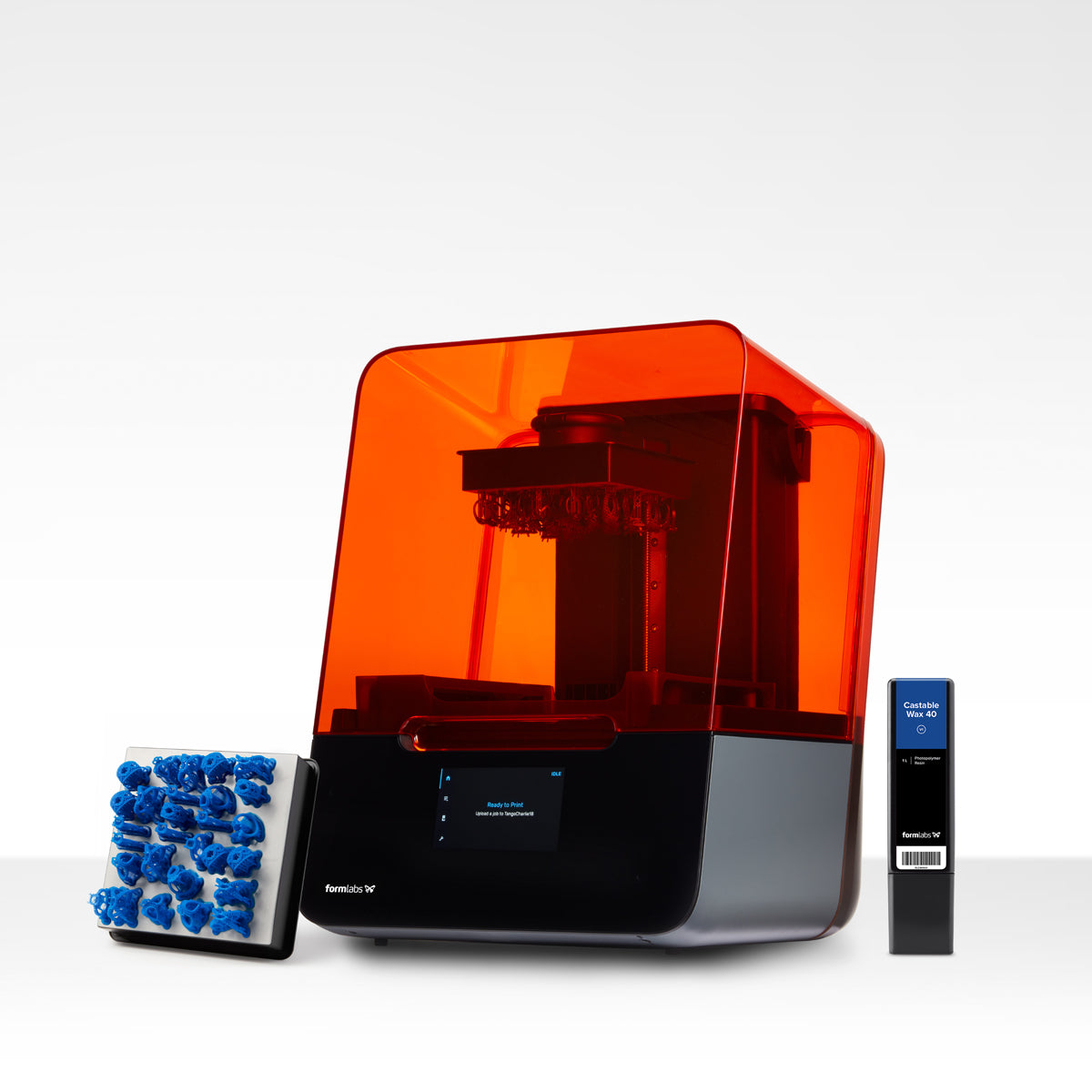

3. Print

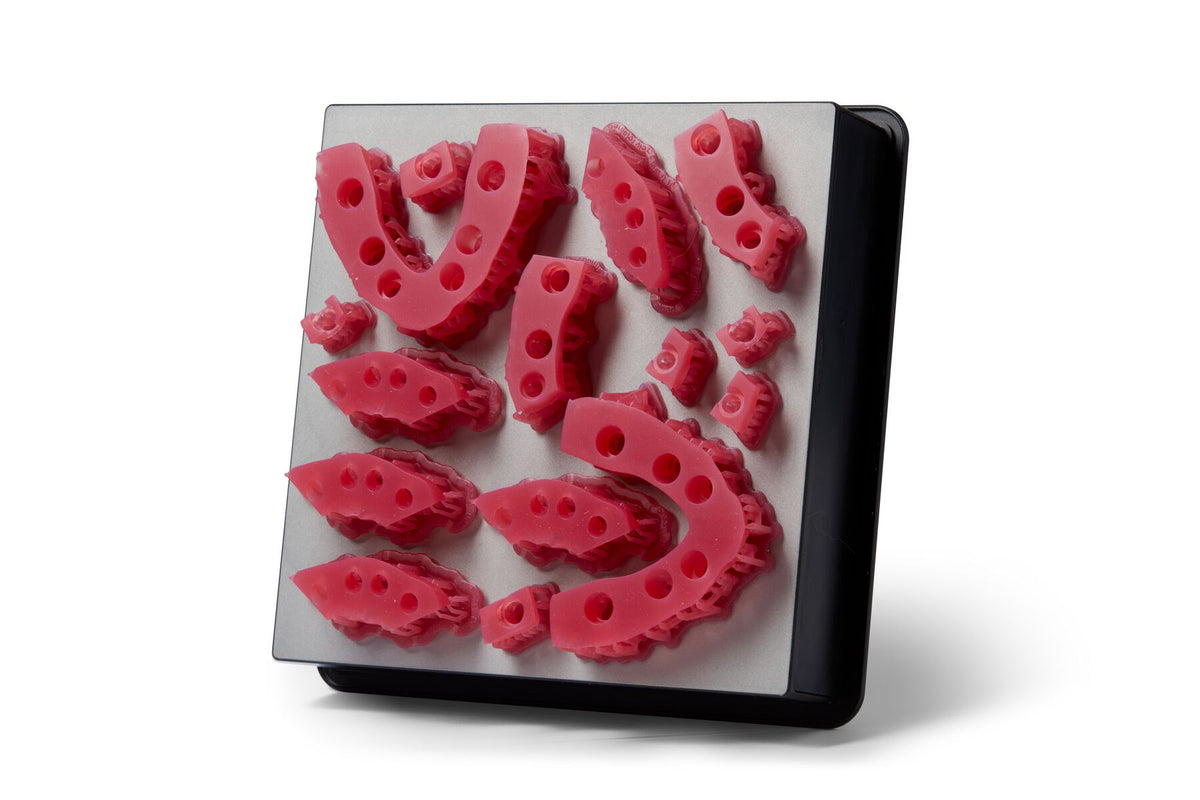

Set up the file and 3D print the indirect bonding tray. Rinse and post-cure according to instructions in the application guide.

4. Prepare

Appliance setup can be done by an assistant before appointment.

5. Placement

Brackets can be placed in one shot by the orthodontist, cutting patient chair time in half.

About Us

3D Printers Perth is a local Australian supplier of high-quality 3D printers and materials, working directly with leading brands like Formlabs to support Australia’s additive manufacturing needs. Backed by over 30 years of experience through Afaridan Plastics and Adarsh Australia, we bring trusted expertise in 3D printing to organisations across Australia.